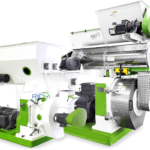

The powerful organic fertilizer pellet making machine developed and produced by Richi Machinery with advanced technology has been widely used in chemical fertilizer, metallurgy, mining, coal, refractory, abrasive, ceramics and other industries after years of operation and continuous improvement.

Iron, copper ore powder, iron oxide scale, iron-containing dust sludge, silicon-manganese alloy, coke powder, coal powder and other powdery materials can be pressed into a block at one time, and can be directly smelted and applied.

The organic fertilizer pellet making machine is a new type of granulation equipment in the chemical fertilizer industry, suitable for single and mixed granulation of nitrogen, phosphorus, potassium fertilizers and compound fertilizers, organic fertilizers, inorganic fertilizers, biological fertilizers, magnetic fertilizers, and organic and inorganic fertilizers.

The organic fertilizer pellet making machine adopts room temperature granulation equipment without drying technicians, with compact layout, reasonable process, advanced technology, no three wastes discharge, stable operation, reliable operation, energy saving and consumption reduction!

1. Uses and features of organic fertilizer pelletizer:

- This organic fertilizer pellet making machine is mainly used for (biological) organic fertilizer, compound fertilizer and pellet processing in aquaculture processing industry;

- The granular material processed by this organic fertilizer pellet making machine has a smooth surface, moderate hardness, low temperature rise during processing, and can better maintain the nutrients inside the raw material; this machine integrates a feeder, a mixer and an organic fertilizer pellet making machine into one; When feeding the material evenly, the material is also agitated twice.

- The feeder is equipped with a governor, which adjusts the amount of feed in accordance with the dryness and humidity of the material during production, so that the host will not get stuck or do useless work. The main machine integrates the ring die and the flat die, which is equivalent to the work of 2 organic fertilizer pellet granulators.

- The particle composition is uniform, the shape is neat, and the pore size of the particle thickness can be divided into: Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to production needs when ordering;

- Due to the low moisture content of the particles, it is easy to store, and can remain in the original state for a long time in water, which greatly improves the utilization rate of materials.

- The organic fertilizer pellet making machine mold, stirring and conveying blades are all corrosion-resistant stainless steel quenched and tempered; the pressure rollers are cast with manganese and quenched and tempered to achieve anti-corrosion and wear-resistant. Thereby increasing the output and reducing the loss of organic fertilizer pellet making equipment.

Extrusion organic fertilizer pellet making machine is one of the main (biological) organic fertilizer production machine currently produced by our company. The organic fertilizer production machine has excellent technology, simple operation, and various models of different models are designed. It is an ideal processing machine for fertilizer processing units.

2. Auxiliary equipment of organic fertilizer pellet making machine

(1) Turner

The principle of the bio-organic fertilizer turning machine is to make the pollutants such as poultry manure, agricultural waste, sugar mill filter mud, sludge, domestic waste, etc. into green, environmentally friendly and soil-improving bio-organic fertilizer through the principle of oxygen consumption fermentation.

This auxiliary equipment of organic fertilizer pellet making machine can reach temperature rise in one day, deodorization in 3-5 days, sterilization (which can completely kill egg bacteria in the feces, etc.), and fertilizer in seven days, which is faster and more efficient than other mechanical fermentation methods. According to customer requirements, some auxiliary facilities can also be added, such as automatic sprinkling device.

Crawler type turning machine is a kind of large turning machine, full hydraulic operating system, lever type steering wheel operation, crawler type walking, strong and durable, strong power, advanced technology, large output, strong turning ability, hydraulic lifting of turning drum adjustment, high degree of automation, simple operation and easy to master. It is a professional turning and throwing equipment for the conversion of organic materials into organic fertilizer by aerobic fermentation.

This auxiliary equipment of organic fertilizer pellet making machine is used for the fermentation and turning of organic wastes such as livestock and poultry manure, sludge garbage, sugar mill filter mud, slag cake and straw sawdust. It is widely used in organic fertilizer plants, compound fertilizer plants, sludge fermentation decomposing and moisture removal operations in garbage factories, gardening farms, and Agaricus bisporus planting plants.

This auxiliary equipment of organic fertilizer pellet making machine is suitable for aerobic fermentation and can be used in conjunction with solar fermentation chambers, fermentation tanks and moving machines. It can realize the function of one machine with multiple slots when used together with the mobile machine. The matching fermentation tank can discharge materials continuously or in batches, with high efficiency, stable operation, sturdy and durable, and even throwing.

The centralized control of the control cabinet can realize manual or automatic control functions, the shovel is sturdy and durable, and has the function of breaking and mixing materials, and the limit travel switch plays a limiting role.

Compost turner is one of the main supporting equipment of fertilizer machinery equipment unit, suitable for trough fermentation: it is the core equipment for the industrialized and harmless treatment of animal husbandry, municipal waste and municipal sewage sludge.

this auxiliary equipment of organic fertilizer pellet making machine has reasonable design structure, high efficiency, low energy consumption, high degree of automation, convenient use, low cost, and wide application. It is a popular model among users.

The stacker is composed of transmission device, lifting device, walking device, stacking device, transfer vehicle and other main components.

The motor directly transmits the power to the cycloid reducer through the sprocket to the turning drum, and the stirring blades on the drum are spirally distributed, which can turn the materials in the fermentation tank and move them to a position of 0.2-1m away, which can play the role of agitation.

The effect of fast turning speed and uniform stirring can achieve the full contact between the material and the air, so that the fermentation effect of the material is good.

The advantage of the crawler turning machine is that it is easier to operate, eliminates the hydraulic direction type, saves space, labor, diesel oil, shortens the working time, and advances the fermentation cycle. The turning clutch of this product adopts soft start, (the domestic similar products all use iron-to-iron hard clutch, which causes serious damage to the chain, bearing and shaft).

The front hydraulic push plate is installed, which does not require manual time-consuming for the whole stack. The drum is hydraulically lifted, and the cab can be optionally equipped with air conditioning.

(2) Rounding machine

The organic fertilizer polishing machine produced by Richi Machinery is a polishing device configured on the basis of the KP-400 flat film extrusion organic fertilizer pellet making machine. Beautiful and practical, it is an ideal equipment for making spherical granules from organic fertilizers (biological).

This this auxiliary equipment of organic fertilizer pellet making machine is specially designed on the internal structure according to the process requirements, and it is an effective special equipment for compound fertilizer.

High output, flexible arrangement in the process, can be used with one or several organic fertilizer pellet making machines at the same time, which solves the complex process, large equipment investment, and multiple organic fertilizer pellet machines caused by the need for a organic fertilizer pelletizer to be equipped with a rounder in the past.

The quality of the finished products produced by the equipment is inconsistent and other disadvantages. This auxiliary equipment of organic fertilizer pellet making machine is composed of two or more throwing cylinders arranged in sequence. The material is discharged from the discharge port after being rounded for many times.

Beautiful appearance, simple structure and reliable quality. It is easy to operate and maintain, and it can be operated and used according to the manual. It has strong anti-overload capability and can adapt to work in various environments. The power consumption is small, the production cost is low, and the economic benefit is high.

(3) Automatic batching system

The automatic batching machine is mainly suitable for mixing, batching and feeding of 3-8 kinds of materials. The machine adopts computer scale for automatic control, and uses pneumatic door to control the quantitative feeding of the main silo. This auxiliary equipment of organic fertilizer pellet making machine has the advantages of simple operation, high batching accuracy, optional adjustment of material ratio, energy saving, easy installation and mobility.

(4) Horizontal mixer

The horizontal mixer is a new generation of mixing equipment developed by our company. This auxiliary equipment of organic fertilizer pellet making machine has high mixing degree and less residue, and is suitable for mixing organic fertilizers and inorganic fertilizers.

The specific features are: the materials are fully mixed, thereby improving the mixing uniformity; the novel rotor structure is used to adjust the gap between the rotor and the casing to close to zero, effectively reducing the residual amount of materials; the special rotor of the machine design can also crush larger materials, the overall structure is more reasonable, the appearance is beautiful, and the operation and maintenance are convenient.

In order to make the machine work normally, please read the instruction manual carefully to avoid damage to the machine.

(5) Material crusher

The material pulverizer is a professional semi-wet material pulverizer which is researched, improved and meticulously manufactured by the scientific research personnel of our factory with advanced pulverization technology at home and abroad, and has been repeatedly researched, improved and carefully manufactured with many years of production experience.

This auxiliary equipment of organic fertilizer pellet making machine solves the problem of crushing organic matter with high water content, so as to declare the right of public security. The successful development of this machine has played a key role in shortening the process flow, reducing equipment investment and saving operating costs for bio-organic fertilizer and compost production.

The allowable moisture content of the bio-fermented organic fertilizer material reaches 25-50%, and the crushing particle size meets the granulation requirements. The crushing particle size can also be adjusted within an appropriate range according to user needs. It plays a role in grinding hard substances such as glass, ceramics, bricks, and gravel in the organic fertilizer of municipal solid waste.

This auxiliary equipment of organic fertilizer pellet making machine is an ideal machine for fertilizer production line units.