Poultry manure pellet machines have revolutionized the way poultry waste is managed and utilized. These machines are designed to convert poultry manure into high-quality organic fertilizer pellets, which can be used to improve soil fertility and crop productivity. With a wide range of pellet machines available in the market, choosing the right one can be a daunting task.

In this article, we will explore the factors that should be considered when selecting a poultry manure pellet machine.

Importance of Choosing the Right Machine

Choosing the right poultry manure pellet machine is crucial for maximizing the efficiency and effectiveness of the pelletizing process. A suitable machine will ensure that the poultry manure is properly processed, resulting in high-quality pellets that are rich in nutrients.

On the other hand, a wrong choice may lead to inefficient pelletizing, low pellet quality, and increased operating costs. Therefore, investing time and effort in selecting the right machine is of utmost importance.

Pelletizing Capacity and Output

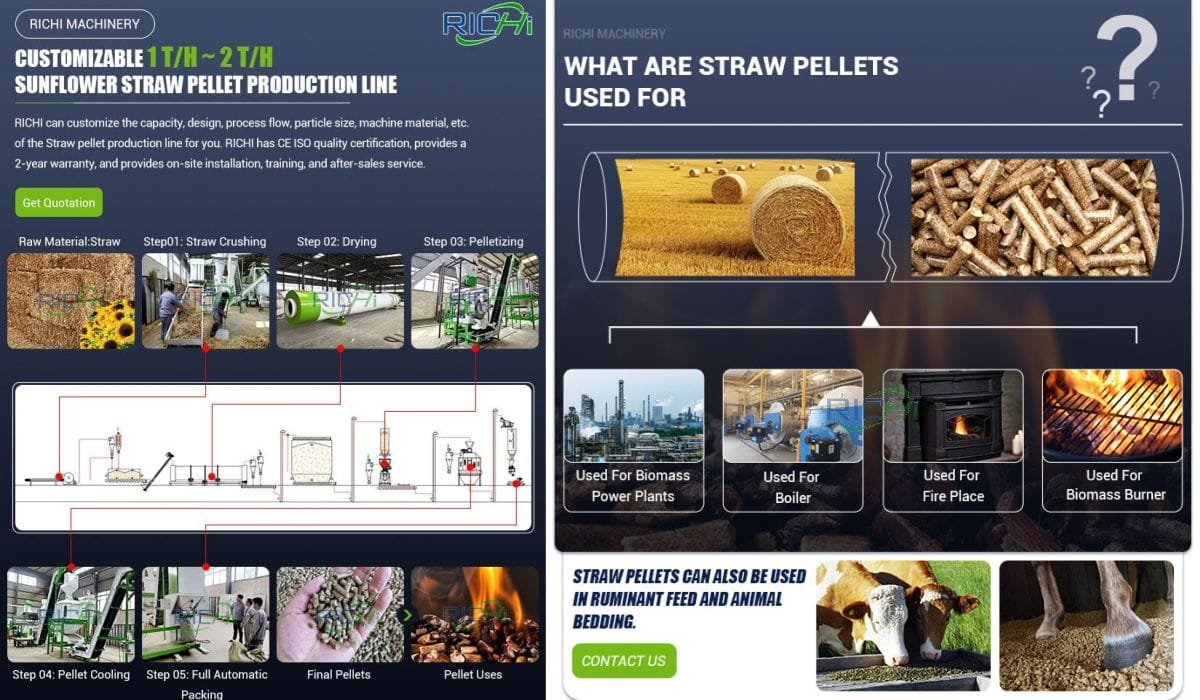

One of the key factors to consider when choosing a poultry manure pellet machine is its pelletizing capacity and output. The capacity refers to the amount of poultry manure that can be processed per hour or per day, while the output refers to the number of pellets produced within a given time frame.

It is essential to evaluate these factors based on the scale of your poultry farm and the amount of manure you need to process.

Material Compatibility and Adaptability

Different types of poultry manure pellet machines are designed to process specific types of materials. It is crucial to ensure that the machine you choose is compatible with the type of poultry manure you have.

Additionally, consider the adaptability of the machine to handle other organic materials such as straw, crop residues, or green waste. This flexibility can greatly enhance the versatility and functionality of the machine.

Energy Efficiency and Power Consumption

Energy efficiency is an important factor to consider, as it directly impacts the operating costs of the pellet machine. Look for machines that are designed to minimize power consumption while maintaining high pelletizing efficiency.

Energy-efficient machines not only reduce electricity bills but also contribute to a sustainable and eco-friendly operation.

Durability and Longevity of the Machine

Investing in a poultry manure pellet machine is a long-term commitment, and therefore, durability and longevity should be taken into account.

Choose a machine that is made from high-quality materials and has a robust construction. This ensures that the machine can withstand the demanding conditions of poultry farm operations and continue to perform reliably for an extended period.

Related post: https://richipelletizer.com/poultry-manure-pellet-machine/

Ease of Operation and Maintenance

A user-friendly pellet machine can streamline the pelletizing process and reduce the need for extensive training. Look for machines that come with intuitive controls and clear instructions.

Additionally, consider the ease of maintenance, including access to critical parts for cleaning and repairs. A machine that is easy to operate and maintain can save time and effort in the long run.

Pellet Quality and Consistency

The quality and consistency of the pellets produced by the machine are crucial factors that determine their effectiveness as organic fertilizers. High-quality pellets are uniform in size, shape, and nutrient content. Look for machines that have a reputation for producing consistent and well-formed pellets.

A machine that can consistently produce high-quality pellets ensures that your crops receive the nutrients they need for optimal growth.

Size and Portability of the Machine

The size and portability of the pellet making machine are important considerations, especially if you have limited space or need to move the machine frequently. Measure the available space in your poultry farm or storage area to ensure that the machine fits comfortably.

Additionally, consider the weight and portability of the machine if you anticipate the need to move it between different locations.

Cost and Return on Investment

The cost of the poultry manure pellet machine is a significant factor to consider, as it determines the financial feasibility of the investment. Compare the prices of different machines and evaluate their features and capabilities to determine the best value for your money.

Additionally, calculate the potential return on investment by estimating the savings in fertilizer costs and the potential increase in crop yields.

Safety Features and Compliance

Safety should be a top priority when selecting a poultry manure pellet machine. Look for machines that have built-in safety features such as emergency stop buttons, overload protection, and safety guards.

Additionally, ensure that the machine complies with relevant safety standards and regulations to minimize the risk of accidents and ensure the well-being of the operator and other personnel.

Customer Reviews and Reputation

Before making a final decision, it is advisable to research customer reviews and the reputation of the manufacturer or supplier. Read testimonials from other poultry farmers who have used the machine to gain insights into its performance, reliability, and customer support.

A machine with positive customer reviews and a reputable manufacturer is more likely to meet your expectations and provide excellent after-sales service.

Choosing the right poultry manure pellet machine is a critical decision that can have a significant impact on the success of your poultry farm. By considering factors such as pelletizing capacity, material compatibility, energy efficiency, durability, ease of operation, pellet quality, size, cost, safety features, and customer reviews, you can make an informed choice that meets your specific requirements. Remember, investing in a high-quality and suitable machine will not only improve your poultry waste management but also contribute to sustainable agriculture and environmental conservation.