Premix feed mills play a crucial role in the animal nutrition industry by producing concentrated blends of vitamins, minerals, and other essential nutrients. These premixes are designed to be incorporated into complete animal feeds at low inclusion rates, typically ranging from 0.5% to 5% of the total feed composition. This article explores the diverse range of products that can be processed in premix feed mills and their significance in animal nutrition.

Core Premix Products

- Vitamin Premixes

Vitamin premixes are fundamental products in any premix feed mill. They typically include:

- Fat-soluble vitamins (A, D, E, K)

- Water-soluble vitamins (B-complex vitamins, vitamin C)

- Choline chloride

These premixes are tailored to meet the specific vitamin requirements of different animal species and life stages.

- Mineral Premixes

Mineral premixes are essential for maintaining proper animal health and growth. They may include:

- Macro minerals (calcium, phosphorus, magnesium, sodium, potassium)

- Trace minerals (iron, zinc, copper, manganese, selenium, iodine)

Mineral premixes can be formulated as inorganic salts or more bioavailable organic forms, depending on the target animal and production goals.

- Vitamin-Mineral Combinations

Many premix feed mills produce combined vitamin-mineral premixes, offering a comprehensive nutrient package in a single product. These are particularly popular for smaller feed mills or farmers who prefer simplified inventory management.

Specialized Premix Products

- Amino Acid Supplements

Premix feed mills often process amino acid supplements, which are crucial for optimizing protein utilization in animal diets. Common amino acids include:

- Lysine

- Methionine

- Threonine

- Tryptophan

These can be incorporated into premixes or offered as standalone products for feed manufacturers to add directly to their formulations.

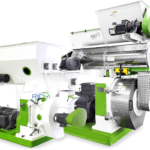

Related post: Animal Feed Pellet Production Line

- Enzyme Additives

Enzyme premixes are increasingly popular in animal nutrition. They can include:

- Phytases for improved phosphorus utilization

- Carbohydrases (e.g., xylanases, β-glucanases) for enhanced digestion of fibrous materials

- Proteases for improved protein digestion

- Probiotic and Prebiotic Blends

To support animal gut health, premix feed mills often produce:

- Probiotic premixes containing beneficial bacteria strains

- Prebiotic blends to promote the growth of beneficial gut microorganisms

- Acidifiers

Organic acid blends are processed in premix feed mills to:

- Improve feed hygiene

- Enhance nutrient digestibility

- Support gut health

Common acidifiers include formic acid, propionic acid, and their salts.

- Antioxidant Premixes

These products help preserve feed quality and extend shelf life. They may include:

- Synthetic antioxidants (e.g., BHT, BHA)

- Natural antioxidants (e.g., tocopherols, plant extracts)

- Mycotoxin Binders

Premix feed mills produce specialized blends of mycotoxin binders and deactivators to mitigate the risks associated with mycotoxin contamination in animal feeds.

Performance-Enhancing Premixes

- Growth Promoters

Where permitted by regulations, premix feed mills may process growth-promoting additives, such as:

- Antibiotic growth promoters (in countries where they are still allowed)

- Non-antibiotic growth promoters (e.g., organic acids, essential oils)

- Flavor Enhancers

To improve feed palatability, premix mills can produce flavor enhancer blends, which may include:

- Natural and artificial flavors

- Sweeteners

- Pigments and Colorants

For specific applications, such as enhancing egg yolk color or improving the appearance of farmed fish, premix feed mills process pigment premixes containing:

- Natural carotenoids (e.g., marigold extract)

- Synthetic carotenoids

Specialized Nutritional Premixes

- Transition Cow Premixes

These are specially formulated to support dairy cows during the critical transition period around calving, containing:

- Higher levels of certain vitamins and minerals

- Anionic salts for managing calcium metabolism

- Breeder Premixes

Designed for breeding animals, these premixes focus on reproductive health and offspring vitality, often including:

- Enhanced levels of vitamins E and A

- Organic trace minerals

- Specific ratios of calcium and phosphorus

- Aquaculture Premixes

Tailored for fish and shrimp nutrition, these premixes may include:

- Specialized vitamin blends (e.g., higher levels of vitamin C)

- Carotenoids for pigmentation

- Essential fatty acids

- Pet Food Premixes

For the pet food industry, premix feed mills can produce specialized blends that include:

- Taurine for cats

- Glucosamine and chondroitin for joint health

- Specific vitamin and mineral profiles for different life stages

Custom and Specialty Products

- Medicated Premixes

In compliance with local regulations, premix feed mills may produce medicated premixes containing:

- Coccidiostats for poultry

- Antibiotics for disease prevention or treatment

- Other approved medications

- Organic Premixes

To serve the growing organic livestock sector, premix feed mills can process organic-certified premixes using:

- Naturally sourced vitamins and minerals

- Organic-compliant additives

- Non-GMO Premixes

For markets demanding non-GMO feeds, specialized premixes can be produced using ingredients that are certified non-GMO. - Species-Specific Formulations

Premix feed mills often develop highly specialized premixes for specific animal species or breeds, such as:

- Racing horse premixes

- Show animal supplements

- Exotic animal nutrition blends

Conclusion

The range of products that can be processed in a premix feed mill is vast and continually evolving. From basic vitamin and mineral blends to highly specialized nutritional packages, premix feed mills play a critical role in optimizing animal nutrition across various species and production systems. The ability to create precise, homogeneous blends of micro-ingredients allows for the efficient delivery of essential nutrients, performance enhancers, and health-promoting compounds in animal feeds.As animal nutrition science advances and consumer preferences shift, premix feed mills continue to innovate, developing new products to meet the changing demands of the livestock, aquaculture, and pet food industries. The flexibility and precision offered by modern premix feed mill equipment enable manufacturers to respond quickly to market needs, producing customized solutions for specific animal health and performance goals.By leveraging cutting-edge formulation technology, quality control measures, and a deep understanding of animal nutritional requirements, premix feed mills contribute significantly to the efficiency and sustainability of animal production worldwide. As the industry continues to evolve, premix feed mills will undoubtedly remain at the forefront of innovation in animal nutrition, processing an ever-wider array of products to meet the complex needs of modern animal husbandry.