The installation of an animal feed manufacturing machine marks a significant milestone in setting up a feed production facility. However, to ensure that the machine operates efficiently and produces high-quality feed, it is essential to conduct thorough performance testing after installation. This article outlines the key steps and considerations involved in performance testing to ensure that the machine meets operational standards and specifications.

1. Preparation for Testing

Before initiating performance testing, it is crucial to prepare adequately to ensure a smooth process.

- Review Installation Documentation: Start by reviewing the installation manual and documentation provided by the manufacturer. This includes specifications, operational guidelines, and safety protocols. Understanding these details is vital for conducting effective testing.

- Check Equipment Setup: Ensure that all components of the machine are correctly installed and secured. This includes verifying that all electrical connections are properly wired, mechanical parts are aligned, and safety guards are in place.

- Gather Necessary Tools: Prepare the tools and equipment needed for testing, such as measuring devices, scales, and monitoring equipment. Having the right tools on hand will facilitate accurate measurements and assessments during the testing phase.

2. Conducting No-Load Testing

Before introducing raw materials, it is essential to perform no-load testing to ensure that the machine operates correctly without any feed.

- Run the Machine Idle: Start the machine and run it without any load for a specified duration, usually 15-30 minutes. This allows you to observe its operation and check for any unusual noises, vibrations, or malfunctions.

- Monitor Parameters: During the no-load test, monitor key parameters such as motor temperature, electrical current, and operating speed. Ensure that all readings are within the manufacturer’s specified limits.

- Check for Leaks: Inspect all connections and seals for any signs of air, oil, or material leaks. Address any leaks immediately, as they can lead to operational inefficiencies and safety hazards.

3. Load Testing

Once the no-load test is successfully completed, proceed to load testing to evaluate the machine’s performance under operational conditions.

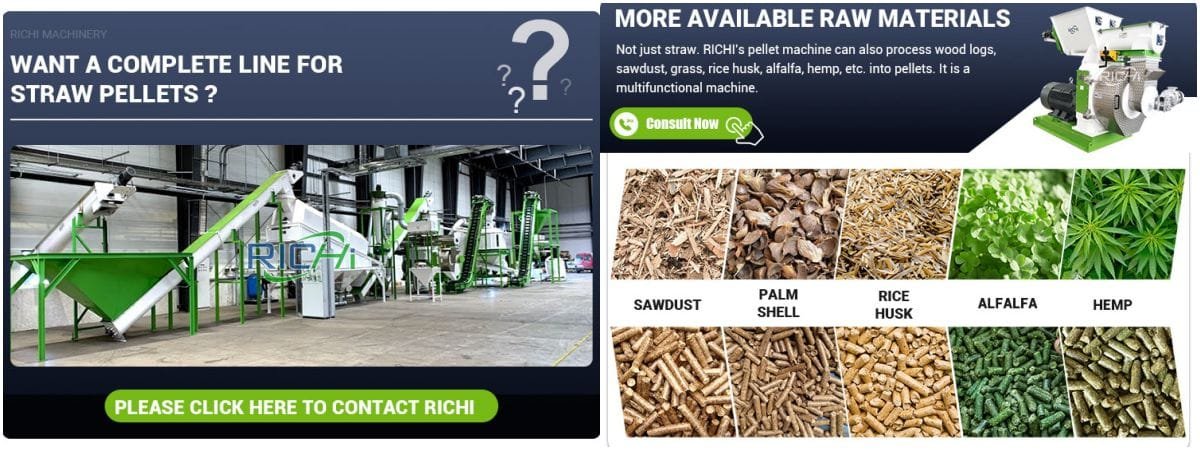

- Gradually Increase Load: Begin by introducing a small amount of raw material to the machine and gradually increase the load to its maximum capacity. This step helps assess how the machine handles different load levels and ensures that it operates smoothly under varying conditions.

- Monitor Performance Metrics: During the load test, monitor key performance metrics, including production output, energy consumption, and feed quality. This data is crucial for evaluating the machine’s efficiency and effectiveness.

- Evaluate Pellet Quality: If the machine is equipped with a pelleting system, assess the quality of the pellets produced. Check for uniformity in size, hardness, and appearance. High-quality pellets should have a consistent shape and minimal fines.

4. Calibration of Equipment

Calibration is a critical step in ensuring that the machine operates accurately and efficiently.

- Calibrate Weighing Scales: If the machine includes weighing scales for batching raw materials, calibrate them to ensure accurate measurements. Use certified weights for calibration and document the results.

- Adjust Control Settings: Review and adjust control settings, such as feed rates, mixing times, and temperature settings, based on the results of the performance testing. Ensuring these settings are optimized will enhance the overall efficiency of the machine.

- Test Safety Features: Verify that all safety features, such as emergency stop buttons and safety guards, are functioning correctly. Conduct tests to ensure that these features engage properly in case of an emergency.

5. Documentation and Reporting

After completing the performance testing, it is essential to document the results and findings.

- Record Test Results: Maintain detailed records of all testing activities, including parameters monitored, measurements taken, and any issues encountered. This documentation will serve as a reference for future maintenance and troubleshooting.

- Analyze Data: Analyze the data collected during testing to identify trends and areas for improvement. This analysis can help inform decisions about adjustments to the machine or operational practices.

- Report Findings: Prepare a comprehensive report summarizing the performance testing results, including any recommendations for adjustments or improvements. Share this report with relevant stakeholders, such as management and maintenance teams.

6. Ongoing Monitoring and Maintenance

Performance testing is not a one-time activity; ongoing monitoring and maintenance are essential for ensuring the long-term efficiency of the machine.

- Establish a Monitoring Schedule: Implement a routine monitoring schedule to regularly assess the machine’s performance. This can include daily checks of key parameters and periodic performance evaluations.

- Conduct Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule to ensure that the machine remains in optimal condition. Regular maintenance tasks may include lubrication, inspection of wear parts, and cleaning.

- Adjust Based on Feedback: Continuously gather feedback from operators regarding the machine’s performance and any issues encountered during operation. Use this feedback to make necessary adjustments and improvements.

Conclusion

Conducting thorough performance testing after the installation of animal feed mill machine is essential for ensuring its efficient and reliable operation. By following a structured approach that includes preparation, no-load and load testing, calibration, documentation, and ongoing monitoring, feed manufacturers can maximize the machine’s performance and longevity.Investing time and resources into performance testing not only enhances the quality of the feed produced but also contributes to the overall success and profitability of the feed production operation. As the demand for high-quality animal feed continues to grow, prioritizing performance testing will be crucial for maintaining a competitive edge in the market.

For details please contact: pellet machine for sale

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com