Applications of Biomass Wood Pellet Machines

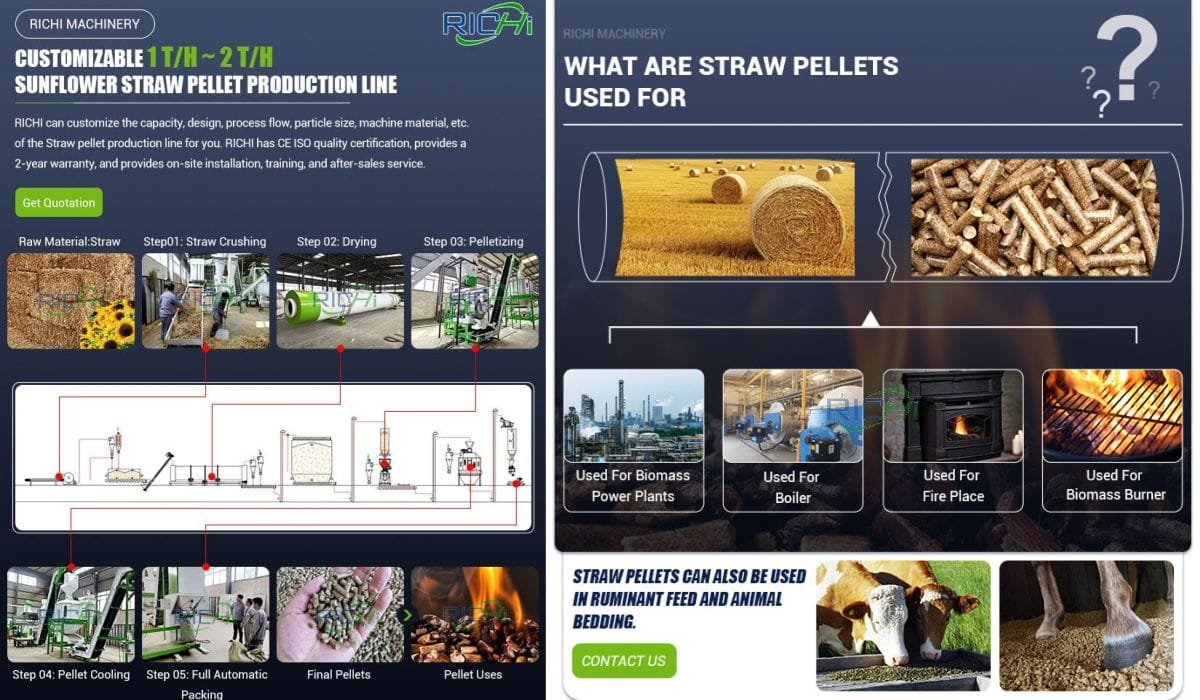

Biomass wood pellet machines serve a pivotal role in various sectors, providing efficient solutions tailored to specific needs across multiple industries. One of the primary applications is in energy production, where these machines are instrumental in converting raw biomass materials into high-energy density wood pellets. Power plants around the world utilize these wood pellets for electricity generation, offering a renewable and lower-emission alternative to traditional fossil fuels. The adaptability of biomass wood pellet machines enables them to process different types of biomass, making them suitable for a wide range of energy production requirements.

In the agricultural sector, these machines facilitate sustainable farming practices by converting agricultural residues into pellets. Farms use biomass wood pellet machines to produce animal bedding, which not only ensures the well-being of livestock but also promotes a cleaner and more hygienic environment. Additionally, the pellets can serve as an organic fertilizer, contributing to soil fertility and improved crop yields. The versatility and efficiency of these machines empower farmers to manage waste effectively while enhancing productivity.

Manufacturing industries also benefit significantly from the use of biomass wood pellet machines. Factories often generate considerable amounts of wood waste during production processes. Instead of disposing of this waste, manufacturers can convert it into wood pellets, which can be used as a cost-effective and eco-friendly energy source for industrial processes. This practice not only reduces waste but also lowers energy costs and minimizes the carbon footprint of manufacturing operations.

Overall, the diverse applications of biomass wood pellet machines underscore their value in fostering sustainability across various domains. From powering energy plants and improving agricultural output to optimizing manufacturing processes, these machines play a crucial role in advancing eco-friendly practices and supporting the global shift towards renewable energy sources.

Biomass wood pellet machines offer the versatility to process a wide array of raw materials into efficient, compact pellets. Among the most commonly used inputs are sawdust and wood shavings, both of which are by-products of wood processing industries. Sawdust and wood shavings are particularly advantageous due to their fine particle sizes and low moisture content, which facilitate easier handling and compacting within the pellet machine. Additionally, these materials contribute to the energy efficiency of the process, as they require minimal additional drying and grinding.

Agricultural residues like straw and corn stalks are also prominent raw materials for biomass wood pellet machines. These materials are abundant and often readily available after harvest. The utilization of agricultural residues helps in reducing waste and promoting sustainable agricultural practices. One advantage of using straw and corn stalks is their lignin content which acts as a natural binder, enhancing the durability and structural integrity of the pellets produced.

Other organic waste materials such as rice husks, coconut shells, and even certain types of grass can be effectively processed in biomass wood pellet machines. Rice husks and coconut shells, for instance, are plentiful in certain regions and present an efficient way to manage agricultural by-products. These materials typically have a high calorific value, making them excellent candidates for energy-efficient pellet production. Grasses, while having a higher ash content, can still be utilized with appropriate pre-processing to ensure effective pellet formation.

In essence, biomass wood pellet machines are a sustainable solution that tap into a diverse range of raw materials. Each type of input material presents unique benefits, contributing to the overall efficiency and versatility of pellet production. By harnessing these various raw materials, biomass wood pellet machines play a crucial role in promoting renewable energy sources and advancing waste management practices.

Uses of Biomass Wood Pellets

Biomass wood pellets have garnered significant attention due to their versatility and sustainability. One of the primary uses of these pellets lies in their application as a heating solution. In residential and commercial settings, biomass wood pellet stoves and boilers serve as efficient alternatives to traditional fossil fuel-based systems. These high-energy pellets provide consistent heat while significantly reducing carbon emissions, making them an environmentally friendly choice.

Furthermore, wood pellets are a reliable renewable fuel source for electricity generation. Many power plants have adopted biomass wood pellet machines to convert these pellets into electrical energy, thus contributing to the reduction of greenhouse gas emissions. The controlled combustion process and high calorific value of the pellets ensure efficient energy production with minimal waste.

In addition to mainstream applications, biomass wood pellets have found niche uses across various industries. For instance, they are increasingly popular in barbecue grills. Pellet grills utilize the uniform size and density of wood pellets to achieve precise temperature control, enhancing the culinary experience. The choice of wood type can also impart unique flavors to the food, making it a preferred option among barbecue enthusiasts.

Another innovative use of biomass wood pellets is as absorption agents. In industries dealing with oil spills or chemical leaks, these pellets are employed to absorb and contain hazardous substances. The high absorbency and biodegradable nature of wood pellets make them an effective and environmentally safe solution in such scenarios.

The diverse applications of biomass wood pellets underscore their significance as a multifunctional resource. Their adoption across different sectors highlights the potential of biomass wood pellet machines in shaping a sustainable and eco-friendly future. By leveraging this renewable resource, societies can move closer to achieving their environmental goals while meeting energy and industrial needs efficiently.

Working Principle and Advantages of Richi Biomass Wood Pellet Machine

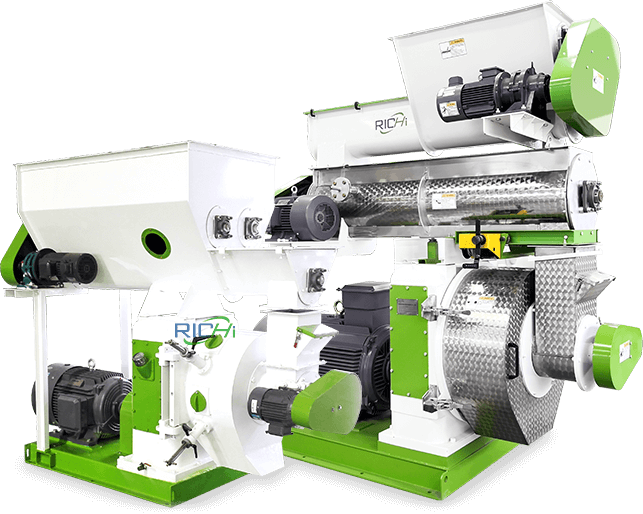

The Richi biomass wood pellet machine operates through a systematic and efficient process that converts raw materials into high-quality pellets. Beginning with raw material feeding, the machine accepts a wide range of biomass materials such as sawdust, wood chips, and agricultural residues. These materials enter the machine’s intake system, where they are uniformly fed into the pelletizing chamber. The uniformity in feeding ensures a consistent product quality and minimized mechanical stress on the machine.

Within the pelletizing chamber, the raw material undergoes compression under high pressure. This stage is crucial as it involves forcing the material through a die with intense pressure, which compacts the particles into dense, cylindrical pellets. The heat generated from the pressure aids in the natural lignin within the wood to act as a binding agent, holding the pellet together without the need for any chemical additives. The resulting pellets are then cooled, sieved to remove fines, and finally stored or packed for distribution.

One of the primary advantages of the Richi biomass wood pellet machine is its energy efficiency. The machine is designed to optimize energy consumption while maintaining high output levels, making it a cost-effective solution for both small and large pellet production enterprises. In addition, its user-friendly interface and automated control systems simplify operation, reducing the need for specialized labor and lowering operational costs.

Maintenance requirements for the Richi biomass wood pellet machine are minimal owing to its robust construction and the use of high-quality materials in its components. This durability translates into longer service life and reduced downtime. When compared to other brands, the Richi machine stands out due to its superior energy efficiency, ease of operation, and lower maintenance needs, providing a competitive edge to its users.

When discussing the Richi wood pellet machine, it is essential to examine the array of accessories available that significantly enhance its functionality and efficiency. These accessories are designed to streamline the pellet production process, making it more reliable and user-friendly. Key accessories include pellet coolers, conveyors, grinders, and dust collection systems, each contributing uniquely to the overall performance of the biomass wood pellet machine.

Pellet Coolers

Pellet coolers play a crucial role in the production process by lowering the temperature and moisture content of the freshly produced pellets. This cooling process not only ensures the structural integrity of the pellets but also improves their storability. By integrating a pellet cooler with the Richi wood pellet machine, producers can achieve higher quality pellets that are less prone to degradation over time.

Conveyors

Conveyors are indispensable for the efficient movement of materials throughout the pellet production process. They facilitate the seamless transfer of raw materials to the grinder, from the grinder to the pellet machine, and finally to the pellet cooler and storage. The inclusion of conveyors minimizes manual labor and significantly reduces the risk of contamination and spillage, thereby enhancing the overall efficiency of the biomass wood pellet machine operations.

Grinders

Grinders are essential for preparing raw materials before they enter the pellet machine. They break down larger biomass materials into smaller, more manageable sizes, optimizing the performance of the pellet machine. By ensuring a consistent and uniform feedstock, grinders help in maintaining the quality and uniformity of the pellets produced by the Richi wood pellet machine.

Dust Collection Systems

Dust collection systems are vital for maintaining a clean and safe working environment. They efficiently capture and remove airborne particles generated during the grinding and pelletizing processes. This not only improves air quality but also protects machinery from potential damage caused by dust accumulation. Implementing a robust dust collection system can enhance the operational efficiency and longevity of the biomass wood pellet machine.

Each of these accessories, when appropriately integrated, contributes to optimizing the functionality, safety, and efficiency of the Richi wood pellet machine, thus ensuring a smoother and more productive pellet manufacturing process.

How to Buy a Richi Biomass Wood Pellet Machine

Purchasing a Richi biomass wood pellet machine entails a nuanced approach, ensuring optimal alignment with your specific needs and budget constraints. Initially, it is paramount to assess the machine’s capacity. Capacity requirements can significantly vary depending on whether the machine is intended for small-scale domestic use or for large-scale industrial production. Define your intended production output to determine a suitable machine that aligns with these specifications.

Budget is another critical factor to consider when purchasing a Richi biomass wood pellet machine. Although opting for more economical options may be tempting, it’s crucial to weigh the long-term performance and durability against the initial cost. Conduct a cost-benefit analysis to balance upfront investment with expected longevity and maintenance costs. Engage with multiple vendors to obtain pricing information, helping to ensure your choice provides the best value for money without comprising on quality.

When looking to buy a Richi biomass pellet maker, understanding the scope and specifics of your intended applications can provide further clarity. Machines may vary significantly in terms of features, adaptability, and energy efficiency. Thoroughly compare these aspects, aligning them with your production demands and environmental considerations. You might also want to consult product reviews and user testimonials to garner insights on the machine’s real-world performance.

Where to buy your biomass wood pellet machine is equally important. Reputable suppliers and authorized distributors should be your first point of consideration. Verify the credibility of the vendor by researching their market reputation, years of operation, and customer feedback. Evaluate the availability of comprehensive support services such as installation guidance, technical training, and after-sales service. Moreover, ascertain if the vendor provides warranties or guarantees, which can provide added security for your investment.

Before finalizing your purchase, engage directly with the suppliers or vendors. Prepare a list of pertinent questions regarding the machine’s processing capabilities, operational efficiency, and potential customizations. Ensure clarity on maintenance needs and inquire about the availability of spare parts. Such dialogues can be invaluable in making an informed decision.

Setting Up a Wood Pellet Plant

Establishing an industrial wood pellet mill involves meticulous preparation and strategic implementation. To begin with, the initial planning stage is critical. It requires a thorough feasibility study that assesses demand, supply chain logistics, and financial viability. Developing a robust business plan can help outline critical components like market analysis, capital investments, operational costs, and profit projections.

Site selection is another paramount factor in setting up a wood pellet plant. Ideal locations are those that are in proximity to raw material sources, ensuring a steady supply of biomass feedstock such as sawdust, wood chips, or agricultural residues. Additionally, locations with good transport links facilitate easier distribution of finished products to market.

Equipment procurement is the next step, where the emphasis should be placed on acquiring high-quality biomass wood pellet machines. These machines should be selected based on their efficiency, durability, and compatibility with the type of biomass available. Key components typically include grinders, dryers, pellet mills, and cooling equipment. Engaging with reputable suppliers can ensure procuring reliable and efficient machinery.

The installation process follows, necessitating precise assembly and calibration of equipment. Working with experienced technicians can streamline this process, preventing potential pitfalls and ensuring operational smoothness. Concurrently, a comprehensive training program for staff is essential to ensure optimal operation and maintenance of the equipment. Competent staffing, both in technical and operational capacities, can significantly enhance productivity and product quality.

Compliance with local regulations is non-negotiable. This requires obtaining necessary permits and adhering to environmental protocols to minimize the ecological footprint. Regular consultations with environmental experts can help navigate complex regulatory landscapes. Safety protocols are also paramount, involving rigorous adherence to occupational health and safety standards to protect the workforce and prevent accidents.

Environmental considerations such as managing emissions and waste byproducts are vital to sustainability. Implementing eco-friendly practices and technologies can minimize environmental impact, reflecting a commitment to sustainable operations.

Maintenance and Troubleshooting of Biomass Wood Pellet Machines

Proper maintenance of biomass wood pellet machines is essential to ensure their longevity and optimal performance. Routine inspections play a critical role in early detection of potential issues. It is recommended to conduct a thorough examination of the machine at least once a month. This includes checking for unusual noises, vibrations, and verifying the proper tension and alignment of belts and chains.

Regular cleaning is imperative in preventing blockages and ensuring smooth operation. Daily removal of dust and debris from the machine, particularly around key operational areas such as the pellet die and roller, can significantly reduce the risk of clogs. Additionally, inspect the auger and feeding systems frequently to avoid interruptions due to accumulated material.

Identifying and addressing common issues promptly can mitigate downtime and improve pellet quality. For instance, if the produced pellets appear uneven or have inconsistent density, examining the roller and die settings is a good starting point. Adjusting the gap between the roller and die can often resolve quality disparities. In the case of machinery wear and tear, such as worn out bearings or gaskets, replacement with high-quality parts is recommended to maintain efficiency.

In the context of a biomass wood pellet machine, lubrication is indispensable. Follow a regular lubrication schedule as specified in the manufacturer’s manual to minimize friction and potential breakdowns. It’s also beneficial to periodically replace oil and check for any signs of contamination in the lubrication systems.

Troubleshooting more complex issues may require professional servicing. If the machine exhibits persistent problems like recurring blockages, significant degradation in pellet quality, or excessive vibration despite routine maintenance, professional assistance should be sought. A qualified technician can provide a thorough diagnosis and implement necessary repairs, ensuring that the biomass wood pellet machine continues to operate effectively.

Staying diligent with these maintenance practices and addressing any troubleshooting needs promptly will ensure that your biomass wood pellet machine remains a reliable and efficient asset in biomass fuel production.