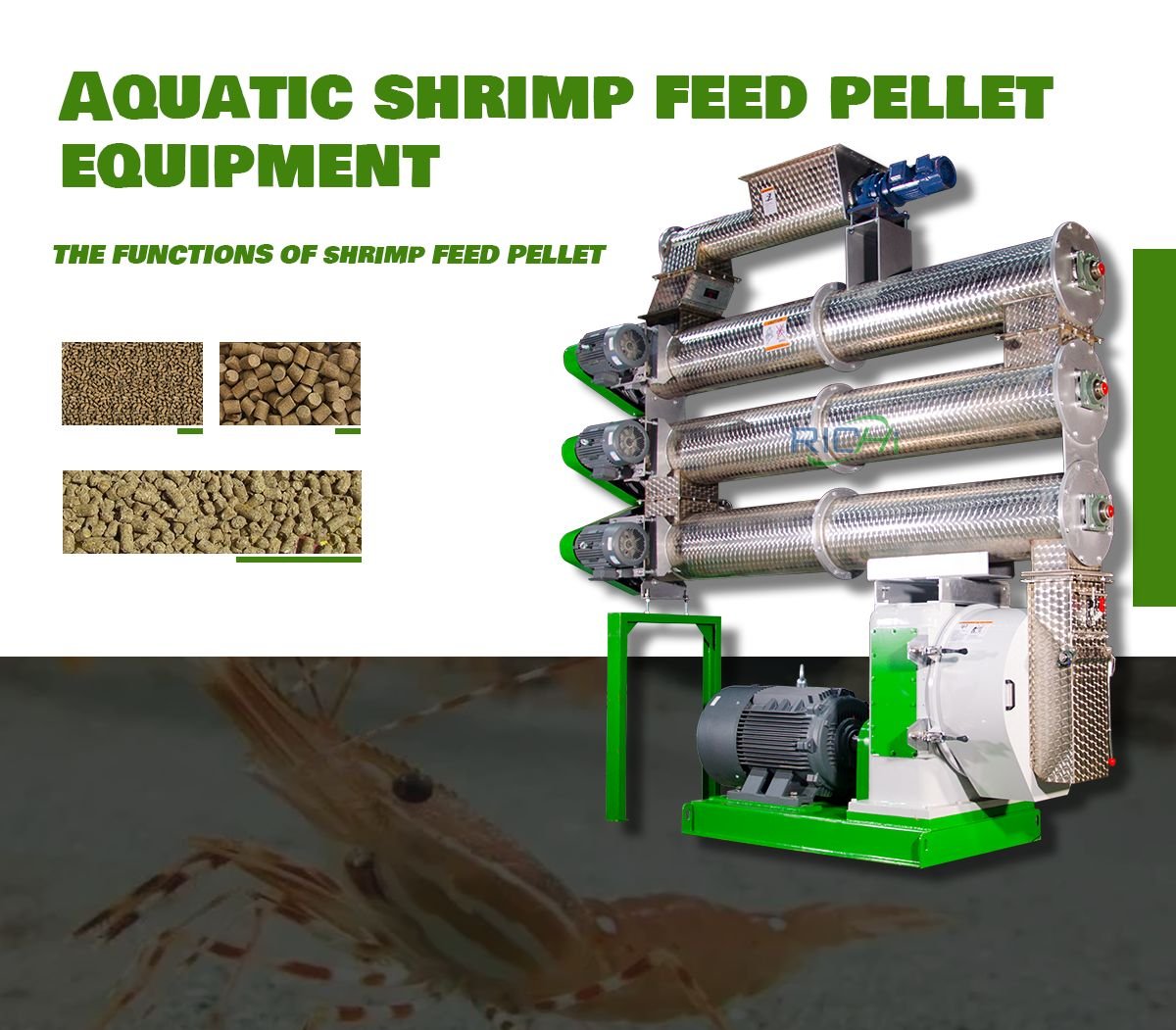

What is a Fish Feed Maker Machine?

A fish feed maker machine, also known as a fish feed pellet machine, is an industrial equipment designed to produce feed pellets for fish and other aquatic animals. These machines are crucial in the aquaculture industry, where the demand for high-quality, nutritionally balanced feed is paramount.

Uses of Fish Feed Maker Machines:

The primary uses of fish feed maker machines include:

- Custom Feed Production: Tailoring feed to meet the specific dietary requirements of various fish species.

- Economic Feeding: Reducing feed costs by using locally available and less expensive raw materials.

- Waste Utilization: Converting agricultural and industrial by-products into valuable fish feed.

- Quality Control: Ensuring the consistency and quality of feed, which is essential for the health and growth of fish.

Industry Application Analysis with Specific Data:

The aquaculture industry has seen significant growth, with the global fish feed market expected to reach USD xx billion by 2025, growing at a CAGR of xx% from 2020 to 2025. This growth is driven by the increasing demand for fish and the need for sustainable feed solutions. Fish feed maker machines are at the heart of this industry, providing the means to produce over xx million tons of fish feed annually.

Classification, Working Principle, and Process Flow:

Classification:

Fish feed maker machines are classified based on their production capacity and the type of die used:

- Ring Die Pellet Machines: Suitable for large-scale production.

- Flat Die Pellet Machines: Ideal for small to medium-scale operations.

Working Principle:

The working principle of a fish feed maker machine involves several steps:

- Material Crushing: Raw materials are crushed into fine particles.

- Mixing: The crushed particles are mixed with other ingredients like vitamins and minerals.

- Pelletizing: The mixture is forced through a die to form pellets.

- Cutting: The extruded pellets are cut to the desired length.

- Drying and Cooling: The pellets are dried and cooled to a suitable moisture content for storage.

Process Flow:

The process flow of a fish feed maker machine typically includes:

- Material Preparation: Collection and preprocessing of raw materials.

- Grinding: Reducing the size of raw materials for better mixing.

- Mixing: Combining ground materials with other nutrients.

- Pelletizing: Producing feed pellets through high-pressure extrusion.

- Cutting: Cutting the extruded pellets to the required size.

- Drying and Cooling: Removing moisture and cooling the pellets.

- Packaging: Packing the finished fish feed pellets for distribution.

How to Choose a Fish Feed Maker Machine:

Selecting the right fish feed maker machine involves considering several factors:

- Production Capacity: Ensure the machine matches your production needs.

- Quality of Pellets: Look for a machine that produces high-quality, durable pellets.

- Energy Efficiency: Choose a machine with high energy efficiency to reduce operational costs.

- Durability and Maintenance: Select a machine made from robust materials that require minimal maintenance.

- Price: Compare prices to find the best value for your investment.

Choosing a Supplier:

When selecting a supplier for your fish feed maker machine, focus on the following characteristics:

- Customization: The supplier should offer customization options to meet your specific feed formulation and production requirements.

- Expertise: Choose a supplier with extensive experience in the fish feed industry.

- After-Sales Service: Ensure the supplier provides comprehensive after-sales support, including installation, training, and maintenance.

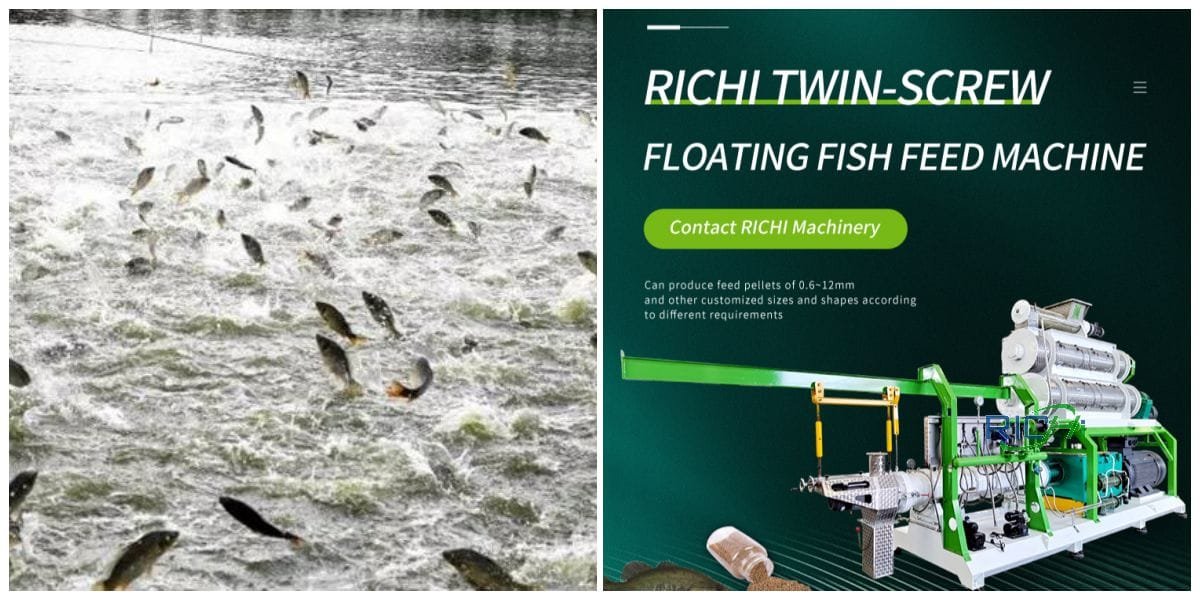

Introducing Richi Machinery Company:

Richi Machinery Company is a leading pellet machinery manufacturer based in Henan, China. As the largest pellet production line manufacturer in the region, Richi offers a range of services and features:

- Customization: Richi can tailor the fish feed mill plant to the customer’s specific needs, ensuring optimal production efficiency.

- Site Design and Turnkey Projects: Richi specializes in site design and turnkey project services, taking care of every aspect from installation to commissioning.

- Experience: With years of experience, Richi has a deep understanding of the aquaculture industry and its feed production requirements.

Practical Application Value:

The practical application value of fish feed maker machines is significant:

- Economic Benefits: By producing feed in-house, fish farms can reduce costs and increase profitability.

- Environmental Impact: Utilizing waste products as feed ingredients contributes to a circular economy and reduces environmental impact.

- Health and Growth: High-quality feed produced by these machines supports the health and rapid growth of fish, leading to better yields for farmers.