A 50T/H animal feed production line is a large-scale, fully automated system designed to produce various types of animal feed pellets at a rate of 50 tons per hour. Here are the key details about such a production line:

Main Applications

- Suitable for processing poultry feed (meat chicken, broilers, laying hens), livestock feed (pig, cow, sheep), ruminant feed, and aquatic feed (fish).

- Can produce different feed types like pellets, crumbles, and extruded/expanded feeds.

Common Ingredients

- Grains (corn, sorghum, barley, wheat), rice products (white rice, rice bran), oilseed meals (soybean meal), bran, oats, cassava meal, vegetable meals, cakes, green feed, fish meal, calcium phosphate, salt, vitamins, minerals.

Process Flow

The typical process flow includes:

- Raw material receiving and cleaning

- Grinding/crushing

- Batching and mixing

- Pelleting

- Cooling

- Screening/sifting

- Coating/fat spraying (optional)

- Packaging

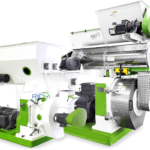

Key Equipment

- Grinding machinery (hammer mills)

- Batching scales and ingredient bins

- Large horizontal or vertical mixers

- Pellet mills (ring die or flat die)

- Counterflow coolers

- Crumblers

- Screeners/sifters

- Coating drums

- Automatic bagging systems

The pellet production lines employ multiple parallel streams/lines for different feed types, often with 5-7 pelleting lines.

What Is The Price Range For 50T/H Animal Feed Production Line?

The typical price range for a 50T/H (50 tons per hour) animal feed production line is:$900,000 – $1,400,000 USD.

Specifically, the sources mention the following details regarding the cost:

Mentions a 50T/H poultry and livestock feed plant project costing around $360,000 per year in production capacity, but does not provide the upfront capital cost.

States that for a 50-60T/H animal feed plant, the cost range is $900,000 – $1,400,000 USD.

The cost can vary depending on factors like:

- Degree of automation and technology level

- Specific equipment models and configuration

- Plant layout and civil construction requirements

- Location and labor costs

- Additional facilities like warehouses, offices etc.

Higher levels of automation, more advanced equipment, larger plant area, and turnkey installation tend to increase the overall capital cost of the 50T/H feed mill plant project.

So in summary, while an exact figure is not provided, most sources suggest a 50 tons per hour animal feed production line typically falls in the $900,000 – $1,400,000 USD price range for the plant setup cost.

What Are The Factors That Affect The Price Of 50T/H Animal Feed Production Line?

The key factors that affect the price of a 50T/H animal feed production line are:

- Degree of Automation and Technology Level

Higher levels of automation with more advanced equipment and control systems increase the overall cost of the plant. Fully automated plants with minimal manual intervention are more expensive than semi-automatic ones. - Specific Equipment Configuration

The models, sizes, and specifications of the various equipment like grinders, mixers, pellet mills, coolers, etc. directly impact the price. Higher capacity and more sophisticated machines cost more. - Plant Layout and Civil Construction

The size of the plant area, number of floors, warehouses, auxiliary facilities like offices etc. affect the civil construction costs which are a major component of the total price. - Feed Types and Process Complexity

Plants producing multiple feed types (poultry, livestock, aquatic) or specialized feeds like premixes require additional process lines, increasing costs. More complex processes like extrusion/expansion are pricier. - Output Capacity

While the examples discuss 50T/H, even small variations in the rated capacity can change equipment sizes/numbers and overall costs. - Location and Labor Costs

Construction labor rates and costs of civil works vary by region/country, affecting the overall plant price. - Turnkey Installation Services

If the supplier provides full turnkey services from design to installation and commissioning, it adds to the total project cost. - Customization Requirements

Any customized modifications or additions to the standard plant design based on customer needs increase the price accordingly.

So in essence, the degree of automation, equipment models, plant size, process complexity, capacity, location, and extent of supplier services are the major price determinants for a 50T/H animal feed production line.

Customization

The specific equipment models, layout, and configuration can be customized based on the customer’s requirements for ingredients, feed types, output capacity, and degree of automation.These large 50T/H feed pellet mills are typically installed as turnkey projects for major commercial feed producers, integrating the entire process from raw material handling to finished product packaging.