Feed pellet machines have become an essential tool in the agriculture industry, providing a convenient and efficient way to produce high-quality animal feed. These machines are designed to process various raw materials into uniform pellets, making it easier for animals to digest and absorb the necessary nutrients.

In this article, we will explore what feed pellet machines are, their importance in livestock farming, how they work, the advantages they offer, tips for efficient operation, maintenance and cleaning, as well as common issues and troubleshooting.

What is a Feed Pellet Machine?

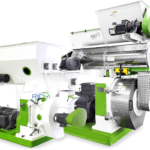

A feed pellet machine is a mechanical device that transforms raw materials such as grains, corn, soybean meal, and other agricultural by-products into compacted pellets.

These pellets serve as a complete source of nutrition for livestock, including poultry, cattle, pigs, and fish. The machine operates by compressing the raw materials through a die with small holes, resulting in cylindrical or spherical pellets of consistent size and shape.

The Importance of Feed Pellet Machines

Feed pellet machines play a crucial role in animal husbandry by ensuring that livestock receive a balanced and nutritious diet. Pelletized feed offers several advantages over loose feed, including improved digestibility, reduced waste, and enhanced animal health.

By using a feed pellet machine, livestock farmers can control the composition of the feed, ensuring a uniform and optimal mix of ingredients tailored to the specific dietary requirements of their animals.

How Feed Pellet Machines Work

Feed pellet machines operate using a process known as pelleting:

- First, the raw materials are ground into a fine powder using a hammer mill or a grinder.

- Then, the powdered mixture is fed into the pellet machine’s hopper.

- Within the machine, the raw materials are compressed and forced through holes in a die plate.

- The pressure and heat generated during this process cause the materials to gelatinize, forming pellets as they pass through the die.

- The pellets are then cut to the desired length and cooled before being discharged from the machine.

Advantages of Using Feed Pellet Machines

Using feed pellet machines offers numerous advantages for livestock farmers:

- Firstly, feed pellets have a higher density than loose feed, making them easier to handle, store, and transport.

- The uniform shape and size of the pellets allow for more accurate feeding, ensuring animals receive an equal distribution of nutrients.

- Additionally, the pelleting process can improve the palatability of the feed, increasing consumption and promoting better growth and productivity.

- Feed pellets also have a reduced risk of contamination and spoilage, leading to longer shelf life and less waste.

Choosing the Right Feed Pellet Machine

When selecting a feed pellet machine, several factors should be considered. These include the desired pellet size, production capacity, power source, and the types of raw materials to be processed.

It is important to choose a machine that matches the specific needs and requirements of the livestock farm. Consulting with experts and considering customer reviews and recommendations can help make an informed decision.

Tips for Efficient Operation of Feed Pellet Machines

To ensure the efficient operation of feed pellet machines, several tips can be followed:

- Firstly, it is essential to properly adjust the moisture content of the raw materials, as this can affect the pellet quality.

- The machine’s die should also be periodically checked and replaced when necessary to maintain consistent pellet size and shape.

- Furthermore, operators should ensure that the machine is regularly cleaned and lubricated to prevent clogging and reduce wear and tear.

- Finally, proper maintenance of the machine’s motor and electrical components is crucial for long-term performance.

Maintenance and Cleaning of Feed Pellet Machines

Regular maintenance and cleaning are essential for the longevity and optimal performance of feed pellet machines. Operators should follow the manufacturer’s guidelines for routine maintenance tasks, such as checking and tightening bolts, inspecting belts and chains, and replacing worn-out parts.

Cleaning procedures should involve removing any feed residue or foreign objects, as well as inspecting and cleaning the die and other critical components. Proper maintenance and cleaning not only prevent breakdowns but also ensure the production of high-quality pellets.

Common Issues and Troubleshooting for Feed Pellet Machines

Despite their efficiency, feed pellet machines may encounter issues that affect their performance. Common problems include uneven pellet size, low production capacity, and excessive wear of machine parts.

To troubleshoot these issues, operators should examine the raw materials’ moisture content, adjust the die clearance, and review the machine’s operational parameters. Additionally, regular inspection and maintenance can help identify and resolve potential problems before they escalate.

Feed pellet machines have revolutionized the livestock industry by providing farmers with a reliable and efficient method of producing nutritious feed.

By understanding how these machines work, their advantages, and proper maintenance procedures, operators can maximize their productivity and ensure the well-being of their animals.

With careful selection, efficient operation, and regular maintenance, feed pellet machines can be a valuable investment for any livestock farm.