The goat feed pellet making machine is a specialized piece of equipment designed for the production of feed pellets for goats. These machines convert raw materials such as grains, grass, and other nutritive components into compact pellets that serve as feed for goats. The use of these machines is pivotal in the modern agricultural and livestock farming industries, optimizing feed quality and ensuring balanced nutrition for livestock.

Uses in the Industry

Goat feed pellet machines play a critical role in enhancing feed efficiency and reducing waste. The pellets produced are uniform in size, highly digestible, and tailored to the nutritional needs of goats, contributing to better health and productivity of the livestock. These machines are used by feed manufacturing companies, large-scale goat farms, and smallholders alike, evidencing their versatility and utility across different scales of operation.

Industry Analysis with Specific Data

The demand for goat feed pellet machines has seen a notable rise, driven by the increasing goat farming activities globally. With goats being raised for meat, milk, and fiber, efficient feed management becomes crucial. The global market for these machines is expected to grow, fueled by advancements in technology and the growing emphasis on sustainable livestock farming practices.

Classification and Working Principle

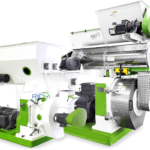

Goat feed pellet making machines can be classified into two main types: flat die pellet machines and ring die pellet machines. The choice between the two depends on the scale of production and specific operational needs.

Working Principle: The basic principle involves feeding the raw material into the machine, where it is compressed between rollers and a die to form pellets. The process involves several steps including material grinding, mixing, conditioning, pelletizing, cooling, and packaging.

Process Flow

- Grinding: Raw materials are ground to a suitable size.

- Mixing: Ground materials are mixed with other ingredients.

- Conditioning: The mixture is conditioned with steam or water.

- Pelletizing: The conditioned mix is then fed into the pellet mill to be compressed into pellets.

- Cooling: The hot pellets are cooled to harden.

- Packaging: Finally, the pellets are packaged for storage or sale.

Choosing the Right Machine and Supplier

When selecting a goat feed pellet making machine, factors such as production capacity, type of raw materials, and the specific needs of your livestock should be considered. For suppliers, prioritize those who offer customization, like Richi Machinery Company, known for its capacity to tailor pellet production lines to specific operational needs and site layouts.

Richi Machinery Company: A Leader in Pellet Machinery Manufacturing

Richi Machinery, the largest pellet production line manufacturer in Henan, China, stands out for its ability to design and implement turnkey projects. The company’s strength lies in its capability to customize the pellet production line, ensuring that each client’s unique requirements are met with precision and efficiency.

Practical Application Value

The practical value of investing in a goat feed pellet making machine includes increased feed efficiency, improved animal health, and higher productivity. These machines support sustainable farming practices by minimizing waste and optimizing nutritional intake for goats.

FAQs About Goat Feed Pellet Making Machine

What are the benefits of using goat feed pellets?

Pellets ensure a balanced diet, reduce waste, and improve feed conversion rates, leading to healthier goats and more efficient farming.

Can I customize the pellet size?

Yes, most pellet making machines allow for adjustments to produce pellets of varying sizes, depending on the age and specific needs of the goats.

How do I maintain a goat feed pellet making machine?

Regular maintenance involves cleaning after use, lubricating moving parts, and checking for wear and tear on dies and rollers.

Are there portable goat feed pellet making machines available?

Yes, there are portable models designed for small-scale farmers, offering flexibility and convenience for on-site feed production.

How does the cost of a goat feed pellet machine vary?

Costs can vary widely based on production capacity, technology, and customization options. It’s important to consider long-term benefits and operational efficiency when evaluating costs.

This article provides a comprehensive overview of goat feed pellet making machines, emphasizing their significance in modern agriculture and livestock farming. By understanding the classifications, working principles, and practical applications, along with careful selection of suppliers like Richi Machinery, stakeholders can significantly enhance the efficiency and sustainability of goat farming operations.