Choosing an appropriate chicken feed production line manufacturer is a pivotal decision for anyone involved in poultry farming or feed production. The reliability and efficiency of the manufacturer’s equipment can significantly impact the quality of the feed and, consequently, the health and productivity of the chickens. With the right production line, you ensure a seamless, cost-effective, and high-quality feed manufacturing process, ultimately leading to a more successful poultry business.

This blog post aims to guide you through the essential criteria for selecting a chicken feed production line manufacturer. These criteria include technological expertise, quality of materials, customer support, and the ability to deliver scalable solutions tailored to your specific needs.

Additionally, we will explore the industry landscape and highlight Richi Machinery, a prominent player known for its innovative and high-quality feed production lines.

Our discussion will delve into the critical aspects that make a manufacturer reliable, such as their commitment to safety standards, research and development efforts, and the versatility of their equipment. By the end of this guide, you will have a comprehensive understanding of what to look for in a chicken feed production line manufacturer, ensuring that you make an informed decision that best supports your operational goals. Richi Machinery will be used as a case study to illustrate these points, demonstrating their capability and why they are highly regarded in this industry.

Key Factors in Choosing a Chicken Feed Production Line Manufacturer

When selecting a manufacturer for a chicken feed production line, numerous factors merit careful consideration. These elements significantly influence the efficiency, productivity, and longevity of the production process. Foremost among these is the quality of machinery. High-quality machinery ensures reliable operation, reduces downtime, and maintains optimal feed quality. Equipment that adheres to stringent quality standards minimizes the likelihood of disruptions and ensures consistent production.

Technology and innovation stand as crucial factors. Manufacturers who invest in cutting-edge technologies streamline feed production, enhance precision, and increase yields. Technological advancements, such as automated controls and real-time monitoring, can dramatically improve operational efficiency. Leveraging these innovations ensures that the production processes remains competitive and capable of meeting evolving market demands.

Customization options are also vital. Every poultry farming operation has unique requirements, influenced by bird species, feed formulas, and production scales. A manufacturer who offers customizable solutions ensures that the feed production line is tailored to specific needs, thereby optimizing performance and resource use. Tailored configurations can lead to improved feed consistency and better flock health, ultimately enhancing productivity.

Equally important is the aspect of after-sales service. Comprehensive support from the manufacturer—ranging from installation and training to maintenance and emergency repairs—ensures that the production line operates smoothly. Dependable after-sales service minimizes operational interruptions and extends the machinery’s lifespan, which is crucial for sustained productivity.

Finally, industry experience plays a pivotal role. Manufacturers with extensive experience possess valuable insights and expertise that can be leveraged to enhance feed production processes. They are better equipped to navigate challenges and provide informed recommendations, ensuring that the production lines meet high operational standards.

Each of these factors—machinery quality, technological innovation, customization options, after-sales service, and industry experience—collectively influence the efficacy and productivity of a chicken feed production line. When choosing a manufacturer, it is imperative to consider these elements to achieve optimal results in the feed production process.

Specific Processes in a Chicken Feed Production Line

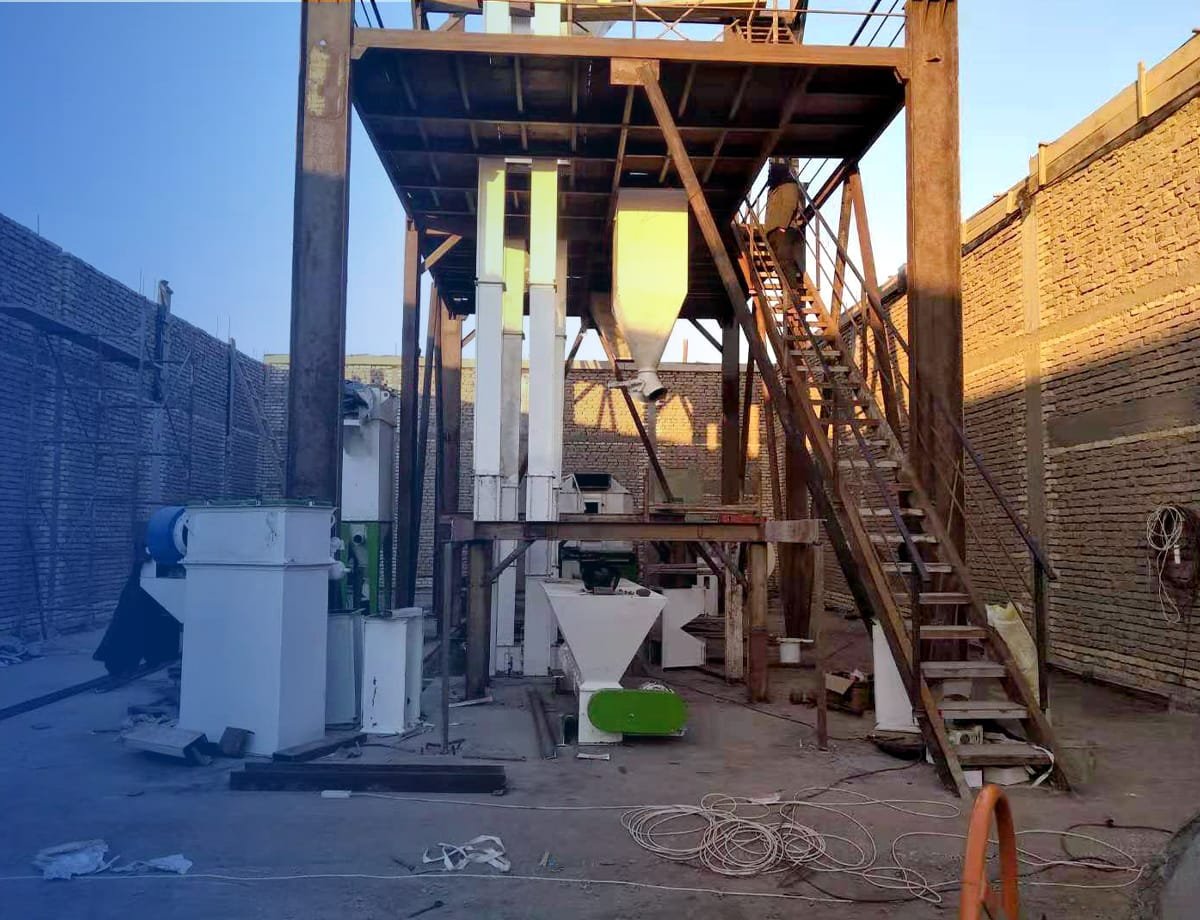

The production of high-quality chicken feed involves various critical processes that ensure the feed meets nutritional standards and is safe for consumption. The specific processes in a chicken feed production line, such as those designed by Richi Machinery, are methodically orchestrated to maximize efficiency while ensuring superior feed quality.

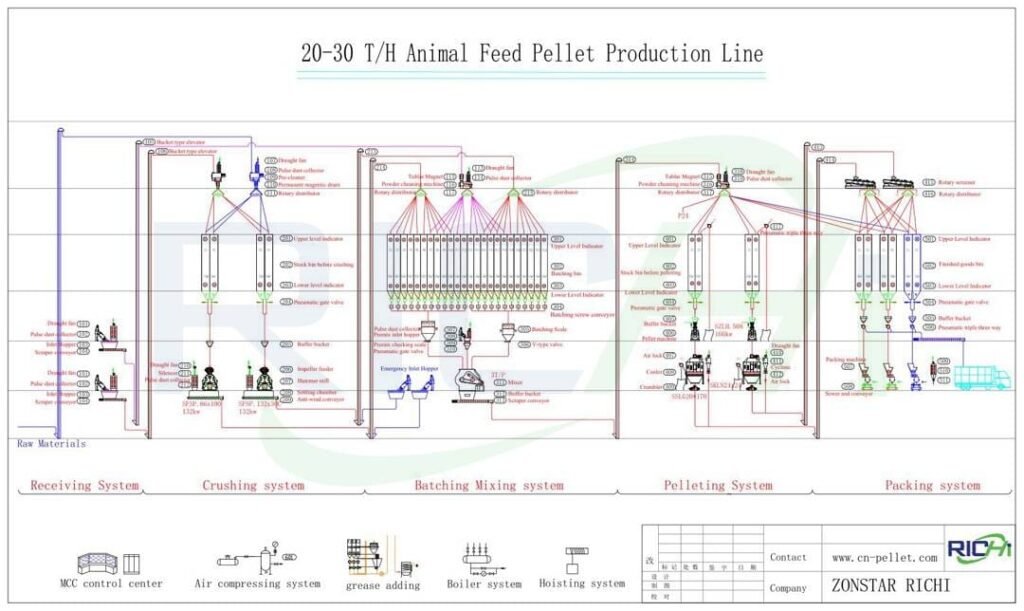

The journey begins with raw material receiving. At this stage, suppliers deliver grains, vitamins, minerals, and other necessary ingredients. It’s vital to ensure these inputs are of high quality, as they form the foundation of the final product’s nutritional value. Rigorous checking and storage protocols are implemented to maintain their integrity.

Following this, the cleaning process removes impurities and contaminants from the raw materials. Dust, small debris, and other foreign particles are separated, safeguarding the feed’s quality and safety. Clean ingredients are essential not just for the health of the chickens but also for the smooth functioning of the machinery in the production line.

Next, the cleaned materials undergo grinding. This process reduces particle size, enhancing the digestibility and uniformity of the feed. Proper grinding is crucial as it affects the feed’s texture and ensures nutrients are accessible for the chickens’ digestive systems.

Subsequently, the ground materials are subjected to batching and mixing. Accurate batching ensures the right proportions of various nutrients, while thorough mixing guarantees uniform distribution of these nutrients throughout the feed. This step is integral for producing nutritionally balanced feed that supports optimal growth and health of the poultry.

The mixed feed is then moved to the pelletizing stage. Pelletizing enhances feed palatability and reduces waste. The process involves compressing the feed mixture into compact, easy-to-consume pellets. Properly formed pellets are crucial for efficient feeding and minimal feed conversion ratios.

After pelletizing, the feed must be cooled. Cooling stabilizes the pellets, preventing mold formation and ensuring they retain their nutritional qualities during storage. Rapid cooling followed by gradual temperature reduction is typically employed to achieve this.

Post-cooling, the feed undergoes screening to sift out under- or over-sized pellets, ensuring consistency in pellet size. Screening maintains feed uniformity, which is essential for consistent feeding practices and overall poultry health.

Finally, the feed is ready for packaging. Proper packaging protects the feed from environmental factors such as moisture and pests. It also facilitates ease of handling, storage, and transport, ensuring that the high-quality feed reaches poultry farms in optimum condition.

Each of these specific processes in a chicken feed production line not only contributes to the end product’s quality but also enhances operational efficiency. By meticulously managing each step, manufacturers like Richi Machinery ensure the production of safe, nutritious, and high-quality chicken feed.

What to Pay Attention to in Chicken Feed Production Lines

When selecting a chicken feed production line manufacturer, several critical aspects must be meticulously monitored to ensure the production of high-quality feed. A key factor is the consistent quality of raw materials. It’s imperative to source raw materials that are not only nutritionally balanced but also free from contaminants. Fluctuations in raw material quality can compromise the nutritional integrity of the feed, which can adversely affect poultry health and productivity.

Maintaining equipment is equally essential. Regular upkeep and timely repairs prevent unexpected downtime and ensure smooth operation. Components such as grinders, mixers, and pelletizers should be regularly inspected for wear and tear. Preventative maintenance helps in identifying potential issues before they escalate, thereby prolonging the lifespan of the production line and maintaining efficiency.

Monitoring the mixing efficiency is another pivotal aspect. Achieving a uniform mix is crucial for ensuring that every batch of feed meets the nutritional standards required for optimum poultry growth. Inconsistent mixing can lead to uneven nutrient distribution, which can affect the poultry’s health and growth rate. Employing precise and well-calibrated mixing equipment can significantly enhance the homogeneity of the feed.

The pelletizing process also requires careful attention. Controlling the pellet size, texture, and temperature during this phase ensures that the finished product meets the desired quality standards. Pellet durability and density are important factors that influence feed intake and digestion among poultry. Proper calibration and monitoring during the pelletizing process are critical in achieving these standards.

Regular maintenance and skilled personnel are indispensable in maintaining the chicken feed production line. Well-trained staff can identify potential issues early and perform routine checks and maintenance more effectively. Investing in continuous training and development for personnel can significantly enhance operational efficiency and feed quality. A combination of high-quality equipment, consistent raw materials, and a diligent workforce forms the cornerstone of a successful chicken feed production line.

Introducing Richi Machinery

Richi Machinery proudly stands as a premier manufacturer highly regarded in the realm of chicken feed production lines. With a legacy that underscores years of innovation, quality, and customer satisfaction, Richi Machinery has emerged as a trusted name for those seeking reliable and efficient solutions for feed production. Established with the vision of revolutionizing the feed industry, the company has consistently adhered to rigorous standards, earning them a formidable reputation both domestically and internationally.

Headquartered in Henan, China, Richi Machinery occupies a dominant position within the region, serving as a beacon of excellence in pellet mill manufacturing. Their extensive experience and commitment to quality have made them a prominent player in the market. The company’s product portfolio is comprehensive, encompassing a variety of feed production machines such as hammer mills, mixers, and pellet mills. Each product is designed with precision and an acute awareness of the specific needs of the poultry industry, ensuring optimal performance and efficiency.

Richi Machinery’s acclaim does not solely rest on their product offerings but also on their unwavering dedication to customer service and satisfaction. They provide an array of services that include technical support, installation guidance, and maintenance, facilitating a seamless experience for their clientele. Their ability to deliver tailor-made solutions has set them apart, catering to both large-scale industrial operations and smaller, specialized needs with the same level of professionalism and care.

Moreover, Richi Machinery’s influence extends beyond just manufacturing exceptional chicken feed production lines. They have established a strong market presence, actively participating in industry forums and exhibitions, further cementing their role as thought leaders. By continuously pushing the envelope in technological advancements and production efficiency, Richi Machinery remains at the forefront, ensuring that they are not just meeting but exceeding the expectations of their diverse and global customer base.

Richi Machinery’s Professionalism and Market Position

Richi Machinery stands at the forefront of the chicken feed production line industry, renowned for its unwavering commitment to quality, innovation, and customer satisfaction. As the leading pellet mill manufacturer in Henan, China, Richi Machinery has consistently set industry benchmarks through stringent quality control measures and continuous process improvements. Their dedication to excellence is reflected in every aspect of their operations, from product design to manufacturing and post-sale support.

One of the cornerstone elements of Richi Machinery’s success is their substantial investment in research and development. The company prioritizes technological advancements, enabling them to pioneer cutting-edge solutions that cater to the evolving needs of the chicken feed production industry. By incorporating the latest technologies and methodologies, Richi Machinery ensures that their production lines are efficient, reliable, and environmentally friendly.

Customer satisfaction is deeply ingrained in Richi Machinery’s organizational culture. The company emphasizes personalized service, taking into account the unique requirements of each client. Their ability to provide customized solutions ensures that every chicken feed production line they establish is tailored to optimize performance and meet specific production goals. This client-centric approach has fortified Richi Machinery’s reputation as a trusted partner in the realm of feed production.

Richi Machinery’s market dominance in Henan, China, underscores their leadership and expertise in the industry. Established as the region’s largest pellet mill manufacturer, their commanding position is a testament to their sophisticated capabilities and expansive market reach. This strategic market positioning ensures that they continually attract and retain a diverse clientele, both domestically and internationally.

Overall, Richi Machinery’s blend of professionalism, innovative spirit, and customer-focused strategies distinguishes them as a premier choice for those seeking robust and dependable chicken feed production lines. Their ongoing commitment to excellence strengthens their role as a pivotal player in the global feed machinery sector, setting a high standard for others to follow.

Why Choose Richi Machinery for Chicken Feed Production Lines

Richi Machinery stands out as a premier choice for chicken feed production lines due to its integration of cutting-edge technology, excellent after-sales service, extensive industry expertise, and a global customer base. These attributes collectively set Richi Machinery apart in the competitive landscape of chicken feed production equipment suppliers.

One of the key strengths of Richi Machinery lies in its state-of-the-art technology, which is central to the efficiency and quality of their chicken feed production lines. The company’s advanced machinery is designed to optimize feed quality, ensuring precision in the formulation and consistency in the final product. This commitment to technological innovation enhances the productivity and profitability of feed producers, addressing their needs comprehensively.

Equally important is Richi Machinery’s comprehensive after-sales service, which ensures that clients receive ongoing support and maintenance long after the initial purchase. This commitment extends beyond the installation phase, encompassing regular check-ups, consultations, and immediate assistance in case of operational issues. Such dedicated customer support fortifies the trust and reliability clients place in Richi Machinery, fostering long-term collaborations.

Richi Machinery’s vast industry experience is another compelling reason to choose them for chicken feed production lines. With years of expertise, the company has honed its capabilities to cater to a variety of customer requirements, delivering tailor-made solutions that effectively address specific operational challenges. Their deep understanding of the industry dynamics allows them to offer equipment that is not only innovative but also aligned with current and future market trends.

The global reach of Richi Machinery further underscores their credibility and effectiveness. Serving a wide array of clients worldwide, their expansive customer base is a testament to the quality and reliability of their chicken feed production lines. Positive testimonials from satisfied clients and numerous successful case studies add to the company’s reputation. These success stories reflect the tangible benefits and improvements that Richi Machinery’s solutions bring to feed producers across the globe.

Conclusion

In conclusion, selecting the right manufacturer for a chicken feed production line is a critical decision that involves careful consideration of numerous factors. The right manufacturer can enhance the overall efficiency, quality, and reliability of your production processes. Key points to look out for include the manufacturer’s technological capabilities, experience in the industry, customer support, and adherence to quality standards. These elements ensure that the chicken feed production line not only meets your immediate needs but also adapts to future requirements.

Throughout this guide, we have explored various aspects integral to making an informed choice. From scrutinizing the manufacturing processes to understanding the importance of after-sales service, each factor plays a vital role in the longevity and productivity of your feed production line. Crucially, evaluating the manufacturer’s market position, customer reviews, and commitment to sustainability can provide deeper insights into their reliability and professionalism.

Richi Machinery emerges as a standout option among industry competitors. Their extensive experience, innovative approaches, and unwavering dedication to excellence position them as a leader in the field. Richi Machinery’s comprehensive support system and customizable solutions cater to diverse needs, making them a reliable partner for businesses looking to enhance their chicken feed production capabilities.

Considering these factors, it becomes evident why partnering with a trusted manufacturer like Richi Machinery can significantly impact your operational success. We invite you to reflect on your specific needs and evaluate manufacturers accordingly, ensuring that the chosen chicken feed production line aligns with your operational goals and growth aspirations.