The hay pellet machine industry has experienced substantial growth in recent years, driven by the increasing demand for efficient animal feed production and sustainable biomass fuel alternatives. Among the various manufacturers in this sector, RICHI Machinery stands out as a prominent player, alongside several other noteworthy companies. This article explores the key manufacturers of hay pellet machines, starting with an in-depth look at RICHI Machinery.

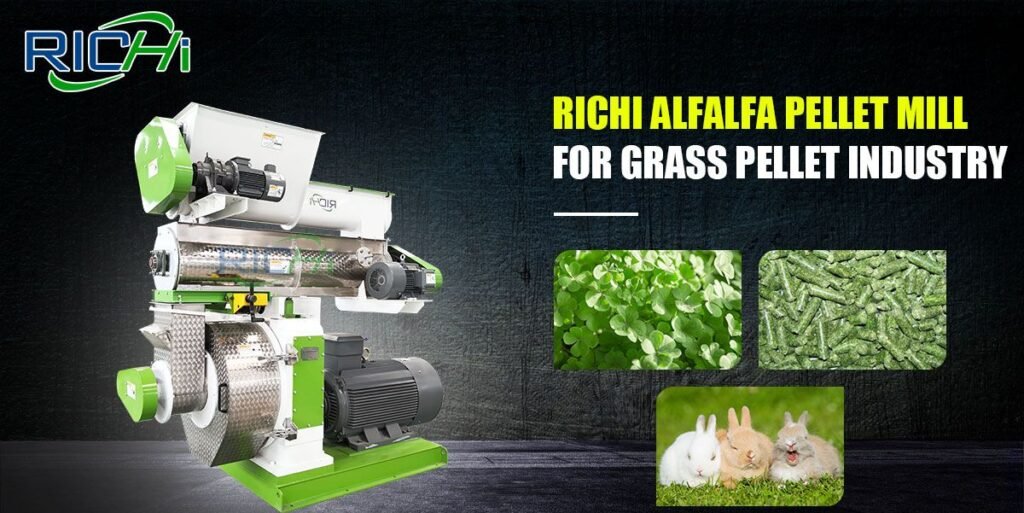

RICHI Machinery

RICHI Machinery has established itself as a leading manufacturer of hay pellet machines, renowned for its quality, innovation, and customer service. Based in China, the company boasts over 27 years of experience in the pellet machine industry and has exported its products to over 120 countries worldwide.

Key Features of RICHI Machinery’s Hay Pellet Machines:

- Wide Range of Capacities: RICHI offers hay pellet machines with capacities ranging from 300 kg to 5 tons per hour, catering to diverse production needs.

- Advanced Technology: Their machines integrate the latest pelletizing technology to ensure high efficiency and superior product quality.

- Customization Options: RICHI provides tailored solutions to meet specific customer requirements.

- Comprehensive Support: The company offers complete turnkey projects, including installation, training, and after-sales service.

- Durability and Reliability: RICHI’s machines are known for their robust construction and long service life.

RICHI Machinery’s hay pellet machines are particularly popular in countries such as the United States, United Kingdom, Australia, New Zealand, and various European nations. The company’s commitment to research and development has led to continuous product improvements, making it a preferred choice for many farmers and feed producers.

CPM (California Pellet Mill)

CPM is an established American company with a long history in the feed processing industry. They provide a range of pellet mills suitable for hay pelletizing, including:

- High-Capacity Machines: Designed for industrial-scale production.

- Advanced Die and Roller Technology: Ensures optimal pellet quality.

- Comprehensive Training and Support: Offers programs to help customers maximize their equipment’s potential.

Amandus Kahl

Based in Germany, Amandus Kahl is known for its high-quality pelletizing equipment:

- Robust Flat Die Pellet Mills: Suitable for various materials, including hay.

- Flexible Machine Designs: Adaptable to different production requirements.

- Hygienic Design: Ensures compliance with food-grade production standards.

Bühler

Bühler, a Swiss company, is a global leader in feed processing technology:

- State-of-the-Art Pellet Mill Designs: Maximize efficiency.

- Integrated Process Control Systems: Ensure consistent quality.

- Sustainability Focus: Develops energy-efficient solutions.

Muyang

Muyang, a Chinese company, has gained international recognition for its feed processing equipment:

- Large-Scale Pellet Mills: Designed for industrial production.

- Advanced Conditioning Systems: Enhance pellet quality.

- Competitive Pricing: Offers value for budget-conscious buyers.

GEMCO

GEMCO, another Chinese manufacturer, has made significant strides in the global market:

- Wide Capacity Range: From small-scale to industrial-grade machines.

- Advanced Automation Systems: Facilitate efficient operation.

- Strong Focus on Biomass Production: Includes hay pellets in its offerings.

Andritz

Andritz, an Austrian company, offers a range of feed processing solutions:

- Advanced Pellet Mill Technology: Supports high-capacity production.

- Energy Efficiency Focus: Aims for sustainable production practices.

- Global Service Network: Provides reliable support.

La Meccanica

La Meccanica, an Italian manufacturer, is recognized for its precision-engineered pellet mills:

- Energy Efficiency Emphasis: Designed for low operating costs.

- Flexible Designs: Adaptable for various feed formulations.

- Strong Customer Support: Focuses on training and assistance. (Related post: grass pelletizer)

Comparison of Manufacturers

While RICHI Machinery leads the market with its comprehensive range and global presence, each manufacturer has unique strengths:

- Technology: RICHI, CPM, and Bühler are noted for their advanced technological innovations.

- Capacity Range: RICHI and GEMCO offer some of the widest capacities available.

- Global Support: RICHI, Andritz, and Bühler have extensive global service networks.

- Cost-Effectiveness: RICHI and Muyang are recognized for their competitive pricing without compromising quality.

- Customization: RICHI and Amandus Kahl are particularly adept at providing customized solutions.

Choosing the Right Manufacturer

When selecting a hay pellet machine manufacturer, consider the following factors:

- Production Capacity: Ensure the manufacturer offers machines that meet your production requirements.

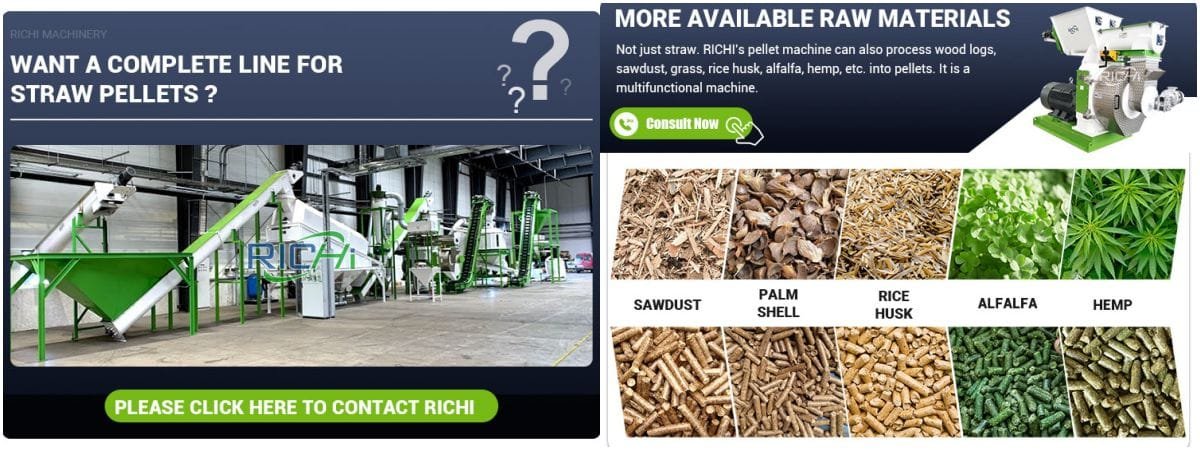

- Raw Material Versatility: Look for machines capable of processing the specific types of hay or other materials you plan to use.

- After-Sales Support: Evaluate the manufacturer’s ability to provide ongoing support and spare parts.

- Energy Efficiency: Compare the energy consumption of different machines to minimize operational costs.

- Customization Options: If you have unique requirements, select a manufacturer willing to customize their solutions.

- Budget: Balance the initial investment with long-term operational costs and expected returns.

Conclusion

While RICHI Machinery stands out as a leading manufacturer of hay pellet machines, offering a comprehensive array of products and services, the market is populated with several reputable companies. Each manufacturer brings distinct strengths to the industry, catering to a variety of needs and preferences in hay pelletizing.

RICHI Machinery’s extensive experience, global reach, and commitment to innovation make it a top choice for many buyers. However, the diverse range of manufacturers available ensures that customers can find solutions tailored to their specific requirements, whether they prioritize high-capacity production, energy efficiency, or specialized pellet characteristics.

As demand for efficient hay processing and biomass fuel production continues to rise, these manufacturers are expected to innovate and enhance their offerings further. Buyers are encouraged to conduct thorough research and compare options, considering factors such as production needs, local support availability, and long-term operational costs when making their decisions. Ultimately, the right choice will depend on the specific requirements of each operation, with RICHI Machinery and its competitors providing a range of solutions to meet diverse needs in the hay pelletizing industry.