In the ever-evolving landscape of the companion animal industry, the importance of providing high-quality nutrition to our beloved pets cannot be overstated. Proper nutrition is essential for maintaining the health, vitality, and overall well-being of our furry friends. Enter pet feed mills, specialized facilities designed to manufacture nutritionally balanced and palatable pet food, catering to the unique dietary requirements of various companion animal species.

The Rise of the Companion Animal Industry

The companion animal industry has experienced remarkable growth in recent decades, driven by the increasing popularity of pet ownership and the recognition of pets as cherished family members. This industry encompasses a wide range of products and services, including pet food, veterinary care, grooming, and accessories. The significance of the companion animal industry extends beyond economic considerations, as it also plays a vital role in:

- Emotional Well-being: Pets provide companionship, unconditional love, and emotional support, contributing to the overall well-being and mental health of their owners.

- Physical Health: Caring for a pet encourages an active lifestyle and can have positive impacts on physical health, such as reduced stress levels and improved cardiovascular function.

- Environmental Awareness: The responsible ownership of pets fosters a greater appreciation for the natural world and promotes environmental stewardship.

- Social Connections: Pet ownership can facilitate social interactions and foster a sense of community, particularly in urban areas where opportunities for social engagement may be limited.

As the companion animal industry continues to thrive, the demand for high-quality pet food has surged, driving the need for efficient and specialized pet feed mills.

The Importance of Pet Feed Mills

Pet feed mills play a crucial role in supporting the growth and development of the companion animal industry. These specialized facilities are designed to manufacture pet food that meets the specific nutritional requirements of various companion animal species, ensuring optimal health and well-being. The benefits of investing in pet feed mills include:

- Consistent Product Quality: Pet feed mills utilize advanced technologies and quality control measures to produce pet food with consistent nutrient profiles, ensuring optimal nutrition for companion animals.

- Customized Formulations: These facilities can manufacture pet food formulations tailored to the specific nutritional needs of different animal species, life stages, and health conditions, optimizing pet health and performance.

- Efficient Production: Modern pet feed mills are designed for efficient and cost-effective production, leveraging automation and process optimization to maximize output and minimize waste.

- Sustainability: Pet feed mills can incorporate sustainable practices, such as the use of alternative protein sources, waste reduction strategies, and energy-efficient technologies, promoting environmental responsibility within the companion animal industry.

- Economic Opportunities: Investing in pet feed mills can create employment opportunities, stimulate local economies, and contribute to the overall growth and development of the companion animal sector.

Related post: https://www.richipelletmachine.com/compound-feed-mill/

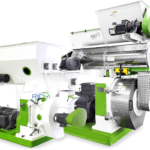

Key Components of a Pet Feed Mill

A successful pet feed mill requires careful planning, execution, and integration of various components to ensure efficient and sustainable operations. The key components of a typical pet feed mill include:

- Raw Material Handling and Storage: Facilities for receiving, storing, and handling raw materials such as grains, proteins, fats, and additives are essential for ensuring a consistent supply of high-quality ingredients.

- Grinding and Mixing: Advanced grinding and mixing equipment is necessary to achieve the desired particle size and homogeneous distribution of ingredients in the pet food formulation.

- Extrusion and Drying: Extrusion and drying systems are crucial for producing high-quality, shelf-stable pet food products with the desired texture, shape, and nutrient retention.

- Coating and Enrobing: Coating and enrobing systems are used to apply palatability enhancers, such as fats or flavors, to the pet food products, improving their appeal and acceptance by companion animals.

- Quality Control and Testing: Comprehensive quality control measures, including laboratory testing and analysis, are essential to ensure that the final pet food product meets stringent nutritional and safety standards.

- Packaging and Storage: Appropriate packaging and storage facilities are necessary to maintain the quality and integrity of the pet food during transportation and distribution.

- Auxiliary Systems: Pet feed mills also require auxiliary systems such as material handling equipment, dust collection systems, process control systems, and utilities to ensure efficient and safe operations.

- Project Management and Support Services: Successful pet feed mill projects often involve collaboration with experienced engineering and consulting firms, providing expertise in project planning, design, construction, commissioning, and ongoing support.

Factors Influencing Pet Feed Mill Success

The success of a pet feed mill is influenced by several critical factors, including:

- Market Analysis and Demand Forecasting: Conducting thorough market research and demand forecasting is essential to ensure that the pet feed mill aligns with the current and future needs of the companion animal industry.

- Raw Material Sourcing and Supply Chain Management: Securing a reliable and cost-effective supply of high-quality raw materials is crucial for consistent pet food production and profitability.

- Technology and Automation: Investing in advanced technologies and automation systems can enhance production efficiency, reduce labor costs, and improve product quality and consistency.

- Energy Efficiency and Sustainability: Incorporating energy-efficient technologies and sustainable practices can reduce operational costs and minimize the environmental impact of the pet feed mill.

- Regulatory Compliance: Ensuring compliance with relevant regulations and standards related to pet food safety, quality, and environmental protection is essential for the long-term viability of the pet feed mill.

- Skilled Workforce and Training: Employing a skilled and well-trained workforce is crucial for the efficient operation and maintenance of the pet feed mill facility.

- Project Management and Risk Mitigation: Effective project management, risk assessment, and mitigation strategies are essential for ensuring timely completion, cost control, and successful implementation of the pet feed mill project.

Opportunities and Future Outlook

As the companion animal industry continues to thrive, the demand for high-quality pet food is expected to rise, creating numerous opportunities for pet feed mills. The future outlook for this sector is promising, driven by factors such as:

- Increasing Pet Ownership: The growing global trend of pet ownership, particularly in urban areas and among younger generations, is expected to drive the demand for pet food and related products.

- Premiumization and Specialization: The pet food market is witnessing a shift towards premium and specialized products, catering to the diverse dietary needs and preferences of companion animals, creating opportunities for specialized pet feed mills.

- Sustainable Practices: The adoption of sustainable practices, such as the use of alternative protein sources, waste reduction strategies, and renewable energy sources, will become increasingly important in the pet feed industry.

- Technological Advancements: Ongoing research and development in areas such as pet nutrition, ingredient optimization, and production processes will contribute to the development of more efficient and innovative pet food products.

- International Collaboration and Investment: Increased international collaboration and investment in the companion animal industry will drive the development of new pet feed mills, fostering economic growth and technological advancements.

In conclusion, pet feed mills play a crucial role in supporting the growth and sustainability of the companion animal industry. By investing in these specialized facilities, stakeholders can contribute to meeting the rising demand for high-quality pet food while promoting sustainable practices and economic development. As the world continues to recognize the importance of companion animals in our lives, pet feed mills will remain at the forefront of this vital industry, fueling its growth and driving innovation for a more prosperous and responsible future.

For details please contact: Richi Pellet Machine

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com