There are principles in the selection of complete sets of poultry feed processing machine, as follows:

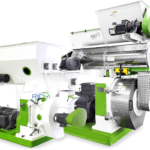

(1) The poultry feed processing machine used in general feed mill factories are mainly ring die poultry feed processing machine, which are more suitable for rough feed granulation. When choosing a model, the main consideration is the rationality of structural design, ease of operation, floor space, power consumption, and selection of parts and components.

(2) The pellet cooler is to maintain the good storage of the product after granulation, and is an indispensable process after granulation.

(3) Feed pulverizer is a device that needs to be used before feed processing and molding, which can save power consumption and improve the digestion and absorption rate of livestock and poultry. At present, almost all feed mills use hammer mills, which can reduce the crushing rate.

(4) According to the user’s feeding scale and feed consumption, choose different types of pelletizer equipment. Generally, the ring die poultry feed pellet making machine can be used for home feeding. The equipment can be produced by lighting electric, small footprint, easy to move and low power consumption.

If the user feeds on a larger scale, such as a poultry feed processing plant, you can choose the SZLH poultry feed processing machine, which can produce about 800kg-1 ton per hour. These two models are the best-selling models of the RICHI maker.

(5) It is very important to choose a suitable feed pellet machine in the production process. I hope that the introduction of the above content can be helpful for users to choose the method of pellet machine.

Details of energy saving in the processing of feed pellets:

1.Granulation process

(1) Under the premise of ensuring the strength, the opening rate of the ring die of the poultry feed processing machine and the screen of the crusher should be increased as much as possible, so as to improve the production efficiency and reduce the power consumption.

(2) Use the ring die repairing machine to repair the ring die in time to improve the granulation efficiency.

(3) Reasonably control the output, adjust the die roll gap, improve the granulation efficiency, and prolong the life of the ring die and the pressing roll. (Hot product: cat litter making machine)

(4) Regularly adjust or replace the blades of the conditioner of the poultry feed pellet making machine, and increase the stirring rod of the conditioner to improve the conditioning effect and increase the output.

2.Ingredients and mixing

(1) Improve the central control operation skills and coordination level.

When the operator receives the production order, according to the production order. The quantity of raw materials in stock and the warehouse capacity of the batching warehouse, determine the type, sequence and quantity of incoming materials to ensure the continuous operation of the mixer, and will not stop production due to the breakage of some raw materials.

Reasonable feeding will ensure that the crusher starts less frequently within a certain period of time, and the air transport time is the shortest.

When producing granular materials and concentrated materials at the same time, determining the appropriate switching time is an important guarantee to maintain continuous production of the poultry feed processing machine. (Hot product: cat litter production line)

(2) Adopt variable frequency variable speed controller to keep the motor load running stably and efficiently.

(3) Material warehouse. The design of the scale bucket shall ensure that the material is discharged without the use of vibratory or mechanical discharge or mechanical discharge.

(4) Correctly set the ingredients, reasonably arrange manual feeding and liquid feeding, and improve the mixing efficiency of ingredients.

3.Crushing link

(1) The size of the sieve hole matches the crushed material, and the smooth surface of the sieve installation faces outward; the sieve holes are arranged vertically; the sieve with high opening rate is adopted.

(2) Replace the hammer or replace the hammer and cloth bag in time to improve the crushing efficiency.

(3) Maintain a good negative pressure state of the air assist system and increase the output. The fan configuration of the dust collector is reasonable, the direction of the fan is correct, the air inlet is suitable, the electromagnetic valve of the pulse dust collector is normal, the filter bag is cleaned every day, and the air leakage is detected.

(4) Feed the material evenly with the transmission to keep the load of the pulverizer constant.

(5) In the pulverization operation, the raw materials that are difficult to pulverize and the raw materials that are easy to pulverize can be mixed to improve the pulverization efficiency.

(6) After initial pulverization and micro pulverization, it enters the classification equipment to reduce excessive pulverization of raw materials.

(7) For the secondary crushing process, check the formula raw materials and oil content, generally controlled within 5%, and the oil should not be too much.

4.Power transmission

Poultry feed processing machine transmit power through transmission devices such as bearings, reducers, and transmission belts. Therefore, first of all, it is necessary to ensure the normal operation and lubrication of the transmission device, reduce the power loss in the transmission process, and achieve the effect of energy saving.

(1) Select the appropriate type of lubricant and dosage to ensure that the poultry feed processing machine has a good working environment and state.

(2) Maintain the proper tension of the drive belt, replace the worn drive belt, and use pulleys and other devices that match the drive belt.

(3) Avoid the vibration of the transmission equipment due to the loose chain, and keep the chain at an appropriate tightness.

(4) Keep the transmission clean, free of dirt and waste accumulation, avoid local overheating, and allow free flow of air around the gear reducer.

(5) When the poultry feed processing machine must work at multiple speeds, replace the mechanical and adjustable belt drive with an AC variable frequency drive.

(6) Minimize or avoid the use of pneumatic conveying systems.