In the rapidly evolving world of biomass processing and animal feed production, the Ring Die Grass Pellet Machine has emerged as a superior choice for manufacturers and farmers alike. This article explores the reasons why this particular type of pellet machine is widely regarded as the best in the industry, examining its design, efficiency, versatility, and overall impact on production processes.

- Superior Design and Functionality

The Ring Die Grass Pellet Machine‘s design is at the core of its superiority. Unlike flat die machines, the ring die configuration offers several advantages:

- a) Continuous Operation: The circular design allows for continuous feeding and pelletizing, resulting in higher production rates.

- b) Even Pressure Distribution: The ring die ensures uniform pressure across the entire pelletizing surface, leading to consistent pellet quality.

- c) Larger Die Surface Area: The cylindrical shape provides a larger surface area for pelletization compared to flat die machines of similar size, enhancing productivity.

- d) Improved Heat Dissipation: The rotating die helps in better heat dissipation, reducing the risk of material degradation due to overheating.

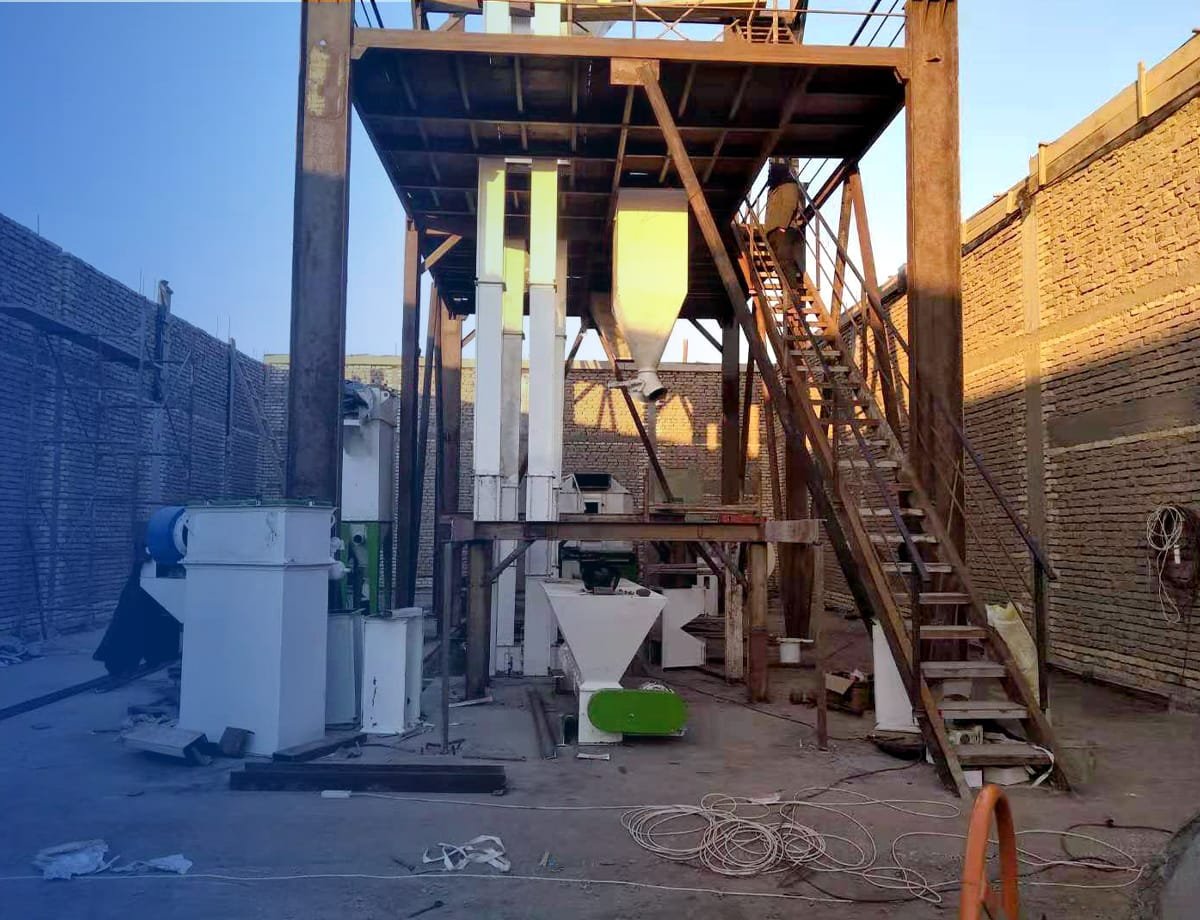

- Higher Production Capacity

Ring Die Grass Pellet Machines are known for their impressive production capacities:

- a) Increased Output: These machines can produce significantly more pellets per hour compared to flat die alternatives of similar size.

- b) Scalability: They are available in various sizes, making them suitable for both small-scale operations and large industrial setups.

- c) Efficient Use of Space: The vertical design often results in a smaller footprint relative to production capacity, optimizing space utilization in production facilities.

- Enhanced Pellet Quality

The quality of pellets produced by Ring Die Grass Pellet Machines is notably superior:

- a) Uniform Density: The consistent pressure application results in pellets with uniform density throughout.

- b) Improved Durability: The pellets produced are typically more durable, reducing breakage during handling and storage.

- c) Better Compression: The design allows for higher compression ratios, resulting in denser pellets that are ideal for both feed and fuel applications.

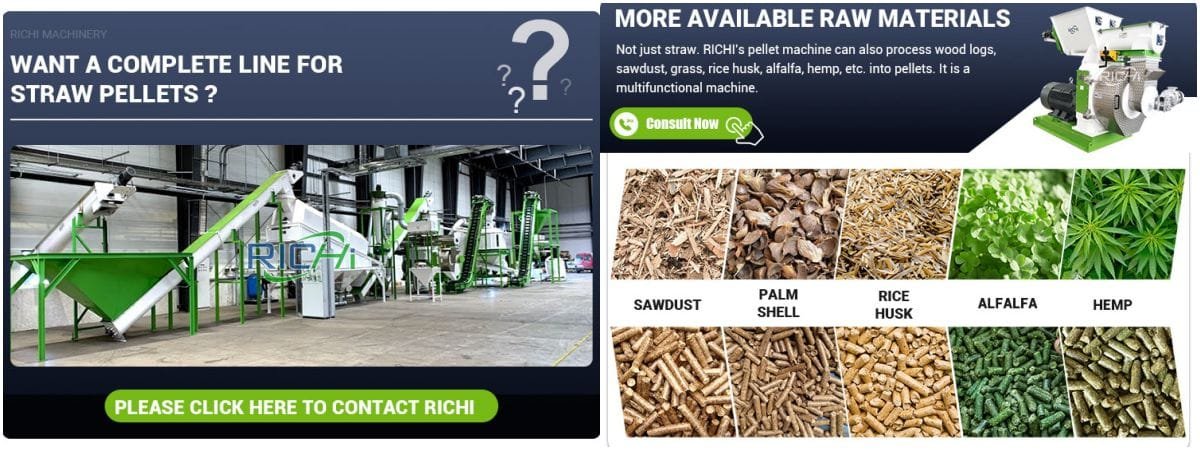

- Versatility in Raw Material Processing

One of the key advantages of Ring Die Grass Pellet Machines is their ability to process a wide range of materials:

- a) Multi-Material Capability: Beyond grass, these machines can effectively pelletize straw, wood chips, sawdust, and various agricultural residues.

- b) Adaptability to Moisture Content: They can handle materials with varying moisture levels more effectively than flat die machines.

- c) Flexibility in Pellet Size: Most models allow for easy adjustment of pellet size by changing the die, catering to different market requirements.

- Energy Efficiency

Ring Die Grass Pellet Machines are designed with energy efficiency in mind:

- a) Optimized Power Consumption: The design allows for more efficient use of power, reducing overall energy costs.

- b) Heat Recovery Potential: Some advanced models incorporate heat recovery systems, further enhancing energy efficiency.

- c) Reduced Friction: The rolling action of the die reduces friction compared to flat die machines, leading to lower power requirements.

- Ease of Maintenance and Longevity

These machines are built for long-term reliability and easy maintenance:

- a) Durable Components: High-quality materials used in construction ensure a longer lifespan of critical components.

- b) Accessible Design: The design typically allows for easy access to wear parts, simplifying maintenance procedures.

- c) Longer Die and Roller Life: The rolling action tends to distribute wear more evenly, extending the life of dies and rollers.

- Improved Safety Features

Modern Ring Die Grass Pellet Machines come with enhanced safety features:

- a) Enclosed Design: Many models feature enclosed designs that reduce dust and noise, improving workplace safety.

- b) Automatic Shut-off Systems: Advanced safety mechanisms can detect jams or overloads and shut off the machine to prevent damage or injury.

- c) Reduced Heat Exposure: The better heat dissipation properties reduce the risk of burns during operation and maintenance.

- Cost-Effectiveness in the Long Run

While the initial investment for a Ring Die Grass Pellet Machine might be higher, it offers better cost-effectiveness over time:

- a) Higher Production Rates: The increased output leads to better return on investment.

- b) Lower Operational Costs: Improved energy efficiency and reduced maintenance needs contribute to lower operational costs.

- c) Versatility Reduces Need for Multiple Machines: The ability to process various materials can eliminate the need for separate machines for different materials.

- Advanced Control Systems

Many modern Ring Die Grass Pellet Machines come equipped with sophisticated control systems:

- a) Precision Control: Digital control panels allow for precise adjustment of operating parameters.

- b) Real-time Monitoring: Advanced sensors provide real-time data on machine performance and pellet quality.

- c) Remote Operation Capabilities: Some models offer remote monitoring and control features, enhancing operational flexibility.

- Environmental Benefits

The efficiency of Ring Die Grass Pellet Machines contributes to environmental sustainability:

- a) Reduced Waste: The ability to process a wide range of materials helps in converting waste into valuable products.

- b) Lower Emissions: The energy efficiency of these machines can lead to reduced carbon emissions in the production process.

- c) Promotion of Renewable Energy: By efficiently producing biomass pellets, these machines support the transition to renewable energy sources.

Related post: Alfalfa Pellet Production Line

Conclusion

The Ring Die Grass Pellet Machine stands out as the best choice in pellet production due to its superior design, high efficiency, versatility, and long-term cost-effectiveness. Its ability to produce high-quality pellets from a wide range of materials, coupled with its energy efficiency and durability, makes it an invaluable asset in both the animal feed and biomass fuel industries.

As the demand for sustainable and efficient pellet production continues to grow, the Ring Die Grass Pellet Machine is well-positioned to meet these needs. Its advanced features, from improved safety mechanisms to sophisticated control systems, ensure that it remains at the forefront of pelletizing technology.

For businesses looking to invest in pellet production equipment, the Ring Die Grass Pellet Machine offers a compelling combination of performance, reliability, and adaptability. While the initial investment may be higher compared to some alternatives, the long-term benefits in terms of production capacity, pellet quality, and operational efficiency make it a wise choice for forward-thinking manufacturers and agricultural operations.